Sustainability Initiatives of India Towards Maintaining the Growth Story of 8% + GDP

Dr. S. K. Manjrekar, Chairman & Managing Director, Sunanda Specialty Coatings Pvt. Ltd., Mumbai

Introduction

India's construction sector is assessed at Rs.4000 billion or $100 billion dollars. As a result of government spending, private investment as well as foreign direct investment, has made India ranks one of the top ten spending nations in construction in the world. We manufacture more than 250 million tons of cement and are second only to China. A recent report "Global Construction 2020", estimates that India will be third largest global construction market after China and USA.India posted growth of 7.2% in the year 2009–10 despite the global financial crisis. Today, we are eyeing a growth of 8.2% this year.

In order to stay on this trajectory, alleviate poverty, and improve the standard of living of her population one of the key hurdles that faces today's India is to overcome the challenge of infrastructure bottlenecks. Consequently, the federal government has announced our 11th five year plan which allocates 9% of the GDP to infrastructure projects. The Planning Commission, an apex federal body has estimated an allocation of $515 billion which is equivalent to Rs.23 trillion to infrastructure sectors over the next five years. This includes construction of Roads, Highways, Airports, Bridges, Ports, Railways as well as water supply and sanitation amongst few others.

The 12th five year plan projects an investment of 10% of the national GDP into infrastructure which equates to a staggering $1 trillion or equivalently Rs.45 trillion.

Drivers for Sustainability

While India is preparing to tackle these growth plans with enthusiasm, it is imperative that this country should analyse and takes into account the price that her future populations and the future populations of the world will have to pay and the world inturn will have to pay. Can this unprecedented growth take place without adequate thought to sustainability. Should we consume all our energy, material, water resources without considering for the needs of our children and grandchildren, the future of the world and our nation is at peril.Obviously GHG emissions, climate change and sustainability are at stake. It is estimated that GHG emissions would increase from 2 billion tons to 6-7 billion tons of CO2 in 2030.

Some of us may question why India must slow down her pace of development and pay for the sins of already developed and industrialized Western nations. Clearly, not only OECD or the industrialized countries should take the lead in mitigating climate change, reducing greenhouse gas emissions but also large developing countries such as India and China will also have to start reducing their emissions over the next 20 to 30 years if we truly want to give our children a chance at a future. Developing countries with large emissions should have some responsibility, although differentiated and different from the industrialized world. While sustainable practices and products may be slightly unintuitive and perceived as counterproductive to the growth of GDP in the short-term, in the long term, the future growth of the country depends on it. Growth that is not sustainable is not true growth.

Recommendations

In mapping out sustainable practices that India must adopt a "cradle to grave" analysis is required and for this, we need to have a total approach than a patch work point system or a grade based certification system. In order to have a comprehensive plan for sustainable construction, every structure may be thought about based on the following parameters:

- Planning, design and specifications based on performance and service life

- Construction Practices

- Material Conservation and Selection

- Demolition and recycling

- Energy Conservation

II. Construction Practices

It is acknowledged that wastage in the construction industry is as high as 30%. That means at the current valuation, we are talking about the wastage to the tune of Rs.1200 billion or $27 billion in India. This is in itself a large, yet relatively simple and straight forward challenge to tackle.

These wastages are activities that absorb resources, man hours and materials but create no value. Most developed countries have different forums / institutes / researchers / academic institutions for seeking solutions to mitigate these wastages and lean construction practices that emerged have yielded encouraging. Lean construction is a "way to design production systems to minimize waste of materials, time and efforts in order to generate the maximum possible value". While some novel initiatives are being taken in some parts of India to adopt leaner construction practices, India does not have a fully focused lean construction forum. Creation of an industry consortium or lean construction forum may be a good beginning.

III. Material Conservation and Selection

Concrete is the largest synthesized material which has a per capita consumption of 1.5 tons per annum in India. Presence of concrete is all pervading simply because it has the capacity to utilize locally available ingredients, develop adequate engineering properties for a variety of applications, easily adapt to any shape and size and has comparatively low initial and maintenance costs. While concrete not be as big of an energy consumer as structural steel, aluminum and glass; concrete and particularly cement still remains a major energy 'sink due to its sheer volume of production and also environmentally unsustainable due to large quantities of CO2 evolution associated with its manufacture. Raw materials for cement manufacture include non renewable natural resources like lime stone, aggregates, manufactured sands (five aggregates), and so on. Hence the Indian concrete Industry needs to take a fresh look at these challenges. Some of the problems faced by Indian concrete industry towards achieving sustainability in concrete utilization are as follows:

A. Increase in use of fly ash and other cement substitutes– Studies indicate that by 2020 the economically feasible stocks of prospectable lime stone are going to be scarce. India has a reasonable availability of by-products like fly ash and GGBFS, and while this helps to an extent to lengthen the period of smooth supply of lime stone. India produces approximately 130 million tons of fly ash out of which only 35-40% is utilized. In another ten years, this production is going to be double to over 250 million tons.

B. Use of manufactured sand-Aggregate scarcity is the biggest concern today in India. On environmental grounds, there have been strict dredging restrictions from various local authorities pertaining to taking out sea sand as well as river sand. This position is more prevalent in the states of central and southern part of India. In northern India, especially in the Indo-Gangetic plains, good quality sand (FA) is available in plenty. However, due to the alluvial terrain of this region coarse, aggregates are not easily available. This challenge manifests on the opposite form in central & southern India where availability of good quality fine aggregate is a constraint.

Hence the answer is to use manufactured sand which is artificially produced from rock, using a vertical shaft Impactor (VSI). VSI based manufactured sand is made by subjecting rock to operations like impact and cleavage attrition and typically results in consistently good quality product having uniform gradation and shape. This sand contains less organic and inorganic impurities too along with lesser chlorides and sulfates. As a result of lower levels of silt, clay and crusher fines, there is a reduction in water demand thus improving strength and durability of the concrete. This also will reduce cement contents. As a result of less of cement, fines and water in the concrete, shrinkage cracking can be reduced to enhance durability and thus sustainability. Additionally, there is substantial environmental benefit, in that the natural terrains of river basins are not disturbed too.

However, in India as of today there are totally convenient misconceptions about manufactured sand. Manufactured sand is mistakenly equated with crushed rock fines (CRF) which is a byproduct of rock crushing to obtain coarse aggregates. CRF is a byproduct of primary and secondary crushing involving use of jaw crushers or cone crushers. Many concrete producers knowingly and unknowingly use of CRF in concrete and that includes major ready mixed concrete manufacturers as well. This is obviously done due to acute shortage of river sand and also to overcome the grading deficiencies in river sand. In the days of "use whatever you get" at many places in metropolitan cities, sand received from nearby rivers is very course in nature with fineness modulus exceeding 4. Such coarse sand is unable to produce a cohesive mix, unless it is supplemented with inert fines such as CRF. This in turn necessitates the use of excess water, creating invariably defective concrete endangering the structures durability right at its birth. Thus India needs to switch over to using VSI manufactured sand as opposed to CRF, or we risk hampering the growth of the industry will due to under performance of the concrete thereby endangering the sustainability.

C. Use of lightweight aggregates- In India, natural lightweight aggregates are not available. The focus then moved to the use of synthetic light weight aggregate. Lightweight aggregates can be produced by sintering waste product like fly ash. There are several examples of the use of these aggregates in structural lightweight aggregate concrete, with compressive strengths ranging from 20-50 MPa (Clarke J.B,Structural lightweight aggregate concrete, Chapman & Hall, 1993 U.K.) The use of sintered fly ash sounds to be a good possibility in India as fly ash is abundantly available in India. Yet another reason to use lightweight aggregate is that almost 70 to 80% of India has become prone to earthquake and thus to reduce the self-weight of various structural elements of a building bridge or any other structure can be substantially reduced enhancing economy as well as safety.

IV. Demolition and Recycling

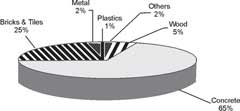

|

| Figure 1: Demolished Construction Waste |

The properties of recycled aggregates have been established and demonstrated through several experimental and field projects successfully. It has been concluded that recycled aggregates can be readily used in construction of low rise buildings, concrete paving blocks & tiles, flooring, retaining walls, approach lanes, sewerage structures, sub base course of pavements, drainage layer in highways, dry lean concrete (DLC) etc.

V. Energy Conservation

Since sources of good quality, aggregates are fast depleting, the concrete industry in India needs to prepare itself to use locally available marginal aggregates. The use of local materials helps reduce the carbon footprint associated with transport. Thus, from sustainability angle, the emphasis should be placed on using locally-available aggregates, even if there are small deficiencies in their quality. It has been amply demonstrated that desired properties of concrete can be obtained by intelligent blending of available aggregates with crushed sand, inert fillers, supplementary cementitious materials and chemical admixtures.

Another important issue is that river sand and other construction materials are usually transported by road. India has a well developed and efficient rail and water transport system that need to be leveraged by the construction industry. This is not only the more sustainable option but also most cost effective.

Conclusion

- India is an astoundingly growing economy and hence the pressure on the use of natural resources is very heavy.

- There is an awakening about the words durability and then sustainability.

- Though durability is understood to a point the real meaning and importance of sustainability is not fully comprehended by engineering fraternity as well as planners.

- Some sporadic efforts are carried out in the form of very repetitive academic experimentation; however, these efforts are in extreme primitive conditions.

- Industry has not opened to this "Sustainability aspect" proactively as they are busy joining the band wagon of growth machine.

- Federal authorities also are not well informed and hence not equipped to adopt 'Sustainability initiative.'

- Also use of renewable energy and resources is not much sought after option and not given due importance as the initial costs are high.

- At the same time, there is definite internal feeling in all that something is definitely needed to be done for next generation. Typically not to leave them with depleted resources.

- At the behest of ACI international – India Chapter of ACI has organized couple of international conferences on sustainability along with the help of other organizations and Institutions.

- But this effort to create and spread awareness should be all pervasive. The proactive participation of all the institutions, professional bodies, academicians, industry as well as firm patronage and participation of government is extremely essential.

- 'Lean Concrete' and 'Reduce Wastage' initiatives in the industry are very necessary.

- India chapter of ACI has decided to take the lead role in this initiative by forming "JSI" like efforts in India. It was suggested by late President Dick Stehly to the chapter after he witnessed the capability of chapter to galvanize the support and participation of many in the recent international conference on "Sustainability."

Dr. S. K. Manjrekar, Immediate Past President, India Chapter of American Concrete Institute (ACI) and General Council members of BAI from Mumbai Centre was the keynote speaker at 'ACI Concrete Sustainability Forum III' held in Pittsburgh, USA in October, 2010. He addressed the forum on the state of the construction industry in India, its growth and more specifically the initiatives taken by Indian construction industry on sustainability.

As construction in the BRIC (Brazil, Russia, India and China) and other developing countries increases, the reckless consumption of energy and resources is also increasing in an alarming way. Attendees to the ACI Concrete Sustainability forum (which was also attended remotely by viewers worldwide as a 'webinar') were provided with a comprehensive overview of the current world situation, including latest information from representatives of BRIC countries which are pioneering concrete sustainability. The forum also discussed and agreed upon future actions regarding introduction and promotion of sustainable construction practices (both in U.S. and internationally) for the concrete industry.

This 3rd sustainability forum was sponsored by ISO/TC-71/SC8, Environmental Management for concrete and concrete structures and ACI committee 130 on sustainability of concrete. The title of Dr. Manjrekar's keynote address was 'Sustainability Initiatives of India towards Maintaining the Growth story of 8% GDP', which is reproduced herein. His talk evoked an extraordinary response from the participants in the auditorium as well as from those attending remotely via the webcast, showcasing the importance of the Indian construction sector on the global stage. As part of ACI's commitment to the dissemination and promotion of thought leadership on the subject of sustainability, they have made the proceedings of the forum available for download at no charge on the website of ACI International 'www.concrete.org'.

NBM&CW May 2011