Liebherr LRB 155 Breaking Ground In India

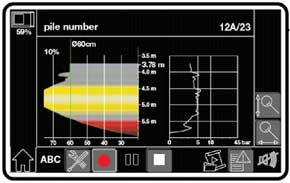

PDE® color monitor for visualization of the PDE® data in the operator's cab – showing the concrete flow

The "LRB series" of Drilling and Piling rigs offered by Liebherr Werk Nenzing, Austria are special deep foundation machines with various applications which make it a class apart from others. These machines are highly productive and applications performed by these machines include Double rotary drilling, Jetting, Pressing, Soil mixing, numerous Ground Improvement techniques, using Ring Vibrator or Hammers, Kelly drilling, Continuous flight auger etc. to name a few.

Liebherr LRB 155

In general, diameter of the CMC's can be designed in the Range of 250 to 420 mm terminating at the designed depth & spacing based on the load requirement and settlement behavior of the subsurface structure.

The core of the Liebherr Drilling and Pilling rigs is the inhouse developed Litronic Control System. The Litronic® control system is based on a CANBUS system of the latest generation which provides clear information on operation and application data but also on service requirements and possible defaults. To add more to the existing features is the smartly developed Liebherr Process Data Recording system PDE® which constantly records the relevant process data during the working process. This PDE® system is operated via the touchscreen monitor provided in the cabin. The operator can enter various details (e.g. jobsite name, pile number, etc.). This data is stored on a compact flash memory card which can be easily transferred to a computer. A further enhancement is the PDR system – Process Data Reporting which generates reports. These reports can be printed directly or stored as pdf files and can be displayed in various languages.

|

|

| Liebherr LRB 155 | A view of the finished column |

The powerful and fuel efficient 450 kW diesel engine ensures enough power for all suitable applications. No additional power pack is required; this saves fuel and operating costs! Apart from the easy and self-assembly features, the low weight and compact design makes road transportation easy. Liebherr has optimized the cost effectiveness of its piling and drilling rigs during operation and consistently minimized the costs per production. Reliable Piling and Drilling rigs with maximum cost effectiveness are the result.