Macro Synthetic Fibres and Pavement Concrete

By Dr. Rakesh Kumar, Senior Principal Scientist, Rigid Pavements Division, CSIR-Central Road Research Institute (CRRI), New Delhi

Continuous research and development related to the improvement of design of traditional structures, design of challenging structures, requirements for meeting the changing global prospective in terms of energy consumption, sustainable aspects, faster and durable construction, durability of construction materials etc, have lead to the development of new and innovative additive materials for the most widely used cement based construction materials i.e. cement mortar and cement concrete which are weaker in tension. From 1960s onwards extensive and exhaustive research work related to the improvement in tensile behaviour of concrete using inclusion such as short discrete steel fibres in concrete matrix have been carried out. So far several innovative developments relating fibres inclusions to cement concrete matrix have been carried out that includes fibre material, texture, shape, length, diameter etc. In this efforts, the development and availability of macro synthetic fibres (MSFs) of different characteristics in construction market is one of such recent additions. Macro synthetic polymeric fibres have the potential to enhance the post cracking properties of hardened cement based materials besides potential for improvement in their other properties including durability. The study aims at disseminating information about the potential uses of macro synthetic fibres in cement concrete for designers, clients and users who are little familiar with use of MSFs for overlay for pavements and bridge deck.

Macro Synthetic Fibres (MSFs)

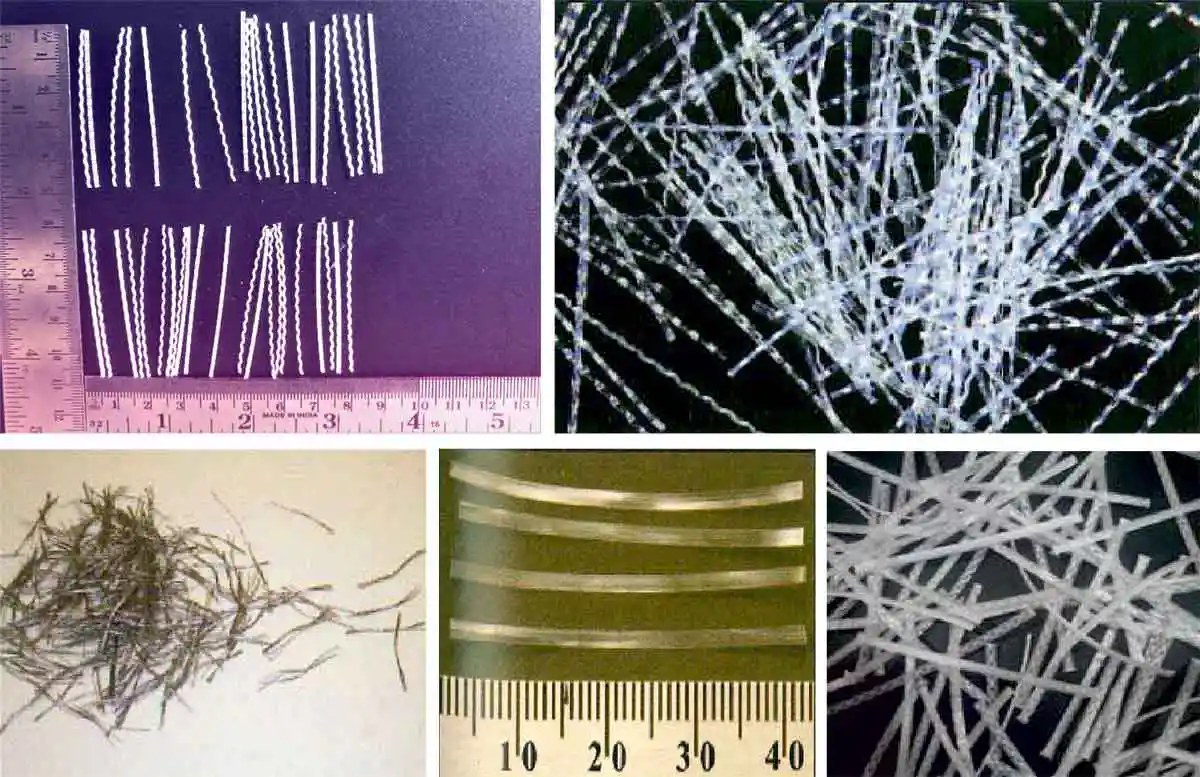

MSFs are commercially available in the market since the late 1990’s. As per the EN 14889 – Part 2, a macro synthetic fibre is a short discrete fibre with diameter greater than 0.30 mm and length between 30 mm and 65 mm. According to ASTM D7508 (reapproved 2015) the general requirements for MSFs are that the individual fibre has a diameter greater than or equal to 0.3 mm and a tensile strength greater than 50,000 psi (350 MPa) with length between 1/2 in (13 mm) and 2.5 in (65 mm). Generally, the ‘equivalent’ diameter of MSFs ranges from 0.3 to 1 mm, with tensile strengths between 350 to 700 MPa. The modulus of elasticity of these fibres is typically around 3 to 10 GPa with aspect ratios ranging from 70-90. MSFs have dimensions similar to steel fibres but are manufactured from materials with a specific gravity in the order of 0.9. They maintain their mechanical properties in alkaline as well as in acidic environments. The shape of the fibres is cylindrical, ‘crimped’ or ‘ribbed’, thin and flat, with a special textured surface. Generally, the MSFs are either straight or deformed. A straight fiber is visually straight, although it may have various surface textures and embossing. Some of the most commonly available MSFs are shown in figure 1.

Figure 1: Commonly available micro synthetic fibres

Figure 1: Commonly available micro synthetic fibresThe fiber’s aspect ratio and geometry are selected based on the basis of its tensile strength and its bonding strength with the concrete matrix to maximize pullout resistance so that the fiber does not break and provides the desired enhancement in the property or properties of concrete for which these have been added. The key to efficient fibre performance is the bond between the fibre and the hardened cement concrete matrix. Some fibres have surface irregularities to strengthen the bond with the cement paste, while others rely on the physical bond between the fibre surface and the hardened cement paste.

MSFs are used to reduce the widths of cracks resulting from repeated live load applications as well as environmental factors such as to control cracking in concrete deck slab and concrete pavement slab due to thermal movements or both, and also to provide post-cracking energy absorption capacity that is the toughness. MSFs may also be used for improvement in structural capacity of concrete to some extent. However, with the current state of the design practice, it is not allowed to fully consider the increased structural capacity from macro-fiber reinforcement in the design process.

Theory relating performance of MSFs in Cement based materials

The performance of macro synthetic fibres (MSFs) in cement-based materials rely on their bond strength with the matrix. In most cases, the characteristics of the cement paste of the matrix is improved with the addition of materials like coal-based fly ash, or silica fume, or similar supplementary cementitious materials, besides water reducing agent (WRA) to improve the bonding with MSFs. For optimum fibre efficiency, the elastic modulus of a fibre should closely match the elastic modulus of the hardened cement paste in which the fibre is embedded. This allows the fibres to transfer stresses across a crack after cracking has begun. As the elastic modulus of MSFs is much less than hardened concrete (MOE for paving concrete is commonly around 26-30 GPa), hence they are generally designed to break, contrary to the failure mode of steel fiber reinforced concrete (SFRC), which is due to the fibres pull out of the cemented matrix. This should be kept in mind while considering the intended application of MSFs in concrete.

MSFs are generally prescribed for use in shotcrete for ground support applications and in concrete for slabs on grade where wider cracks (mostly wider than 0.4 or 0.5 mm) can be accommodated and for concrete slabs where the closer joint spacing is provided. MSFs are particularly beneficial when larger crack widths (say >0.5 mm), can be accommodated in the concrete as they need to elongate or ‘stretch’ before they are able to transfer significant amounts of stress across the cracks.

Design of MSF Reinforced Concrete

The material properties of MSF reinforced concretes such as residual tensile strength, energy absorption capacity, (i.e toughness) are determined by beam tests in accordance with ASTM C1609-06, ASTM C1550-19. The results obtained can be used to calculate the performance of the post-cracked concrete specimen and for the concrete element where the in-service performance relies on the post-cracking behaviour of the concrete.

MSFs are not designed to replace steel bars or mesh where either is used for structural reasons. Since the inclusion of such fibres may enhance concrete’s post cracking capacity, they can be used in some designs based on plastic analysis such as ground supported slabs and rock support when used in shotcrete. MSFs can be used to replace steel mesh for shrinkage control in ground supported concrete slabs. If MSFs are used as a replacement for shrinkage, then it is important that the fibre type and dose rate provide a similar level of direct tensile capacity. This will ensure that crack control is provided, but due consideration should be given to maximum acceptable serviceability limit state crack widths.

The dosage of MSFs should be sufficient (0.2 to 1.0% by volume) to give an equivalent flexural strength of at least 0.3; otherwise the concrete should be treated as plain. The ‘design using MSFs is still in its infancy and there are no universally accepted methods’ [CSTR 65]. The suitability of a particular fibre for a particular application will depend on appropriate design rules being followed. The study [CSTR 34, 2016] reports that certain types and dosages of MSFs can enhance the equivalent flexural strength ratio values, which should be determined by testing (as for steel fibres reinforced concrete).

Properties of Macro Synthetic Fibres Reinforced Concrete

Hardened concrete containing MSFs can generally be described as having post crack energy absorption capacity. At normal dosage of MSFs addition, the fibres should not have any adverse affect on the compressive strength and durability of the concrete, if the reduction in workability due to the fibres addition is compensated by the addition of a good water reducing agent (WRA). But, at higher fibre dosages, MSF may cause the plastic concrete to appear stiff and harsh; in such cases, a proper mix design and use of chemical admixtures in order to avoid any placement and/or compaction issues, are needed. In some situations, an increase in cement paste content and/or the addition of a small amount of air entraining agent, or some suitable water reducing agent (WRA), can create a workable concrete mix.

According to CSTR 65, there is limited information on how the physical properties of MSFs change over time and, therefore, how the long-term structural performance of the concrete may be affected. The modulus of elasticity and creep of the fibres should be kept in mind.

CE Approved Macro Synthetic Fibres Manufactured to EN 14889-2

In Europe, MSFs can have a CE label for structural use, certifying compliance with EN 14889-2, Class II, i.e. fibres >0.3 mm in diameter. MSFs (for structural use) should not be used at a lower dosage than the declared minimum value stated on the CE label. In our country, we lack such information for structural use of MSFs.

Mix Design/Proportioning

Generally, the dosage rates of MSFs range from 2 to 7 kg/m3 of concrete, i.e. about 0.25 to 0.75% by volume, depending on the requirements for meeting the desired improvement levels, post cracking. The dosage rate needed to achieve the desired residual flexural strength varies depending on the fibre material and fibre dimensions. Increasing the dosage of fibres to achieve a certain toughness performance target is likely to have an adverse impact on the workability of the concrete. To overcome the loss in workability of the concrete, the addition of a water reducing admixture is recommended without compromising the strength, durability, and other properties of the concrete mix design. Another way to compensate the loss of workability due to the addition of MSF is by increasing the paste content of the concrete mix. For cold areas where the concrete slabs are exposed to freezing weather, a slight increase in the dosage of a suitable air entrainment admixture may be used to ensure the durability of concrete, primarily because of the increased surface area of the fibre in the concrete mix.

Using MSFS in Concrete

Batching and Mixing of Concrete Containing MSF

Figure 2: Concrete mix containing MSFs

Figure 2: Concrete mix containing MSFsPlacing and Finishing of Concrete

No special equipment is required for placing and finishing of the concrete mix containing MSFs. Concrete mix containing MSFs may be placed and compacted using the same methods as used in a plain concrete mix; however, an extra precaution should be taken during finishing to minimise the appearance of fibres on the surface of the slab. Appearance of an excessive number of fibres on the finished surface of the slab may indicate inadequate mix design, fibre type, dosage, and placing/finishing techniques. During broom finishing and tinning, some of the macro synthetic fibres are likely to be seen on the surface of the concrete pavement. Hence, inclined texturing is preferred. However, fibres protruding out will not harm as they will quickly wear off due to abrasion. In some cases, these fibres are cut to match the surface of the pavement.

Sampling and Testing

Sampling, testing and quality control procedures for concrete containing MSFs are not different from the conventional concrete. However, extra attention is to be paid during casting of MSF reinforced concrete beam specimens for flexural testing. Care must be taken to fill the beam moulds in the specified manner in order to minimise variances in test results due to changes in fibre alignment within the beam mould. Some manufacturers of MSFs offer test methods for determining the dosage in plastic concrete.

Areas of Application

The major applications for MSF reinforced concrete are in the following:

- Sprayed concrete that is shotcrete as ground support in underground works

- Construction of footpaths

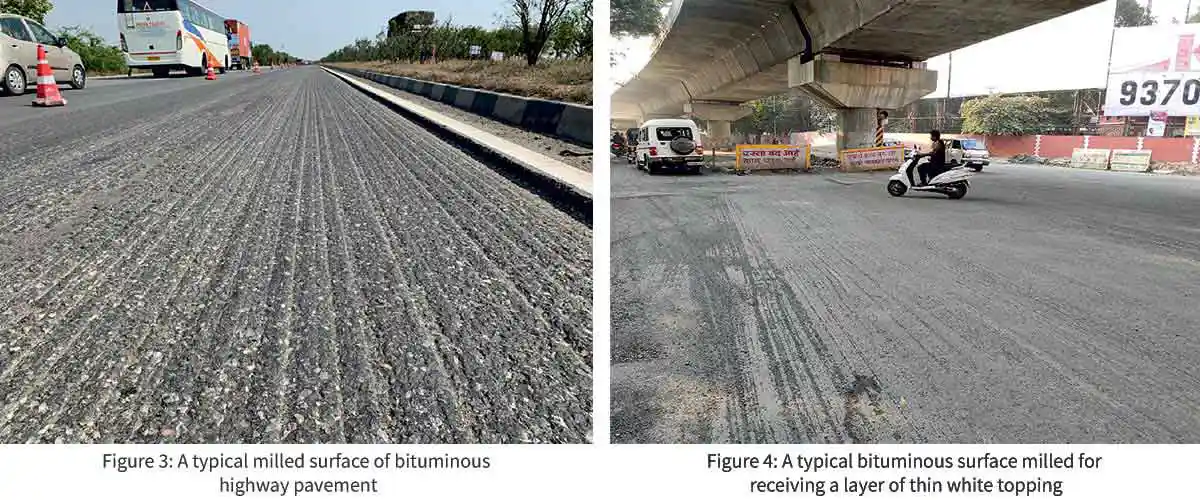

- Concrete pavements such as thin and ultrathin white topping overlays on suitable distressed bituminous roads. Pavement concrete containing MSFs increases the ductility in comparison with plain concrete (extent of enhancement depends on the amount and type of MSFs) which is very much suitable for concrete overlay directly on milled surface for the construction of a thin and ultrathin white topping as a rehabilitation and strengthening of distressed bituminous surface. Typical milled surfaces of bituminous pavements ready for receiving concrete for overlay on a highway and a city road are shown in figures 3 and 4, respectively, clarifying a need for concrete mix with MSFs on plain concrete for better performance and a longer service life.

- Precast concrete such as pipes, track paving slabs, etc.

- Concrete overlay on both newly constructed and rehabilitated bridge decks. In such applications, the improved toughness behaviour of concrete due to the addition of MSFs increases the service live of deck slabs because of a drastic reduction in the rate of crack propagation, improvement in behaviour under impact load, etc.

Summary

The availability of MSFs of different characteristics in the construction market as inclusion in cement concrete is a recent addition in the list of innovative techniques for incorporating/improving the engineering properties of cement-based materials such as concrete and mortar. Macro synthetic polymeric fibres have the potential to enhance the post cracking properties of hardened cement-based materials, besides improving other properties, including durability. Enhancement in crack arresting properties, post crack behaviour, including residual flexural strength, abrasion resistance, ductility, resistance to disintegration of cracked slab panels result in the construction of more durable concrete overlays such as thin, ultrathin, conventional and bridge deck overlays for rehabilitation and strengthening.

Acknowledgements

The permission of Director-CRRI Prof. Satish Chandra to publish this work is gratefully acknowledged and also the help provided by Adarsh Kumar and Garima during the preparation of the manuscript.

References:

- TR 65 Guidance on the use of macro-synthetic fibre reinforced concrete, Concrete Society U.K., 2007.

- Romualdi J P, and Batson G B., (1963), “Mechanics of crack arrest in concrete”, Journal of Engineering Mechanics 89, 1963, pp 147-168.

- Hannant, D.J. (1978) “Fibre cements and fibre concretes” A Wiley –Interscience Publication.

- Bentur, A. and Mindess, S. (2007) “Fibre reinforced cementitious composites” 2nd Edition.

- CSTR-34, 2016. Concrete Industrial Ground Floors. UK Concrete Society’s Technical Report, CSTR 34, a guideline to design and construction, 4th Edition, Surrey, UK.

- ASTM C1609-06. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading), American Society of Testing Materials, Philadelphia, 2006.

- ASTM C1550-19. Standard Test Method for Flexural Toughness of Fiber-Reinforced Concrete (Using Centrally Loaded Round Panel, Philadelphia, USA.

- EN 14889 – Part 2. Fibres for concrete Part 2: Polymer fibres Definitions, specifications and conformity, 2006.

- ASTM D 7508. Standard Specification for Polyolefin Chopped Strands for Use in Concrete, American Society of Testing Materials, Philadelphia, 2015.

NBM&CW November 2020