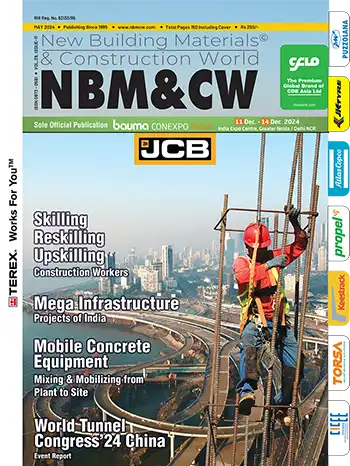

Keestrack India: all electirc Jaw & Cone Crusher for lowest per ton cost

Keestrack India, Swaminathan Dhandapani - CEO

No doubt, technology comes at a slightly higher cost, nonetheless, we aim to make it a standard in our products and are actively working towards it.

Keestrack provides a range of crushing and screening equipment which include jaw crusher of 300 TPH and cone crusher tailored to match the incoming feed. In addition to these primary and secondary crushing solutions, the company offers two models of scalpers of varying capacity. Model K5 is a compact option that can efficiently process up to 400 tons per hour, while the larger model K8 boasts an impressive capacity of up to 1200 tons per hour, making it suitable for high-demand applications.

Market Trend and Growth Trajectory Beyond 2024

The General elections next year might affect the decision making by customers for a period spanning three to six months. Historically it has been seen that if the same government continues in power, the market recovery process is faster. This year has witnessed a remarkable 20% growth but the coming year might witness a slight decline to about 10%, owing to potential shifts in priorities or alterations in project timelines, resulting in reduced work periods. Nevertheless, in the subsequent years, it is improbable that the growth rate will dip below 15% especially in the track mounted crushing business.In the material processing and crushing segment, the emphasis is on track-mounted or mobile crushers. Anticipating substantial transformations in road construction practices, the trend is expected to shift towards hybrid models, including electric or hybrid machinery. It is also anticipated that the market share for track-mounted crushers will escalate from the current 5-6% to approximately 8-10% within the next 2-3 years. This shift is driven by the availability of high-capacity track-mounted machines, which now reach up to 300 TPH, effectively meeting the demands of the mining sector as well.

Keestrack is globally the only company which has maintained a steadfast focus only on track / mobile crushing and screening machines. Although these versatile machines find applications across diverse sectors such as mining, road construction, and C&D, it’s noteworthy that in India, the market is still dominated by modular or fixed machines. We are very confident that this trend will change in India as well as the growth of mobile crushing & screening equipment will definitely surpass the growth in the stationary machines.

Striking a balance: Keestrack’s approach to local and global competition with focus on product expansion

I firmly believe that local competition is equally poised to compete with global players. At Keestrack, our primary objective has been to launch between four to five products within the crushing and scalping categories which will be all electric and the best that latest global technology has to offer and establish a solid foundation for these products before venturing into new areas. In alignment with this overarching strategy, we are preparing to introduce two new product lines in 2024: Impact Crushers and Classifiers.For local companies, their cost-effectiveness doesn’t stem solely from manufacturing and sourcing local components in India, but also from reduced overhead costs compared to global players. In recent years, we’ve witnessed a gradual price increase in their offerings, not as an attempt to maximize profits, but rather as a result of their learnings and design improvements for long-term sustainability. They’ve come to understand that significant upgrades are necessary to ensure reliability over 15 to 20 years, which then will be at par with international products.

We are confident that Indian customers will choose technology and move swiftly away from yesteryear fuel guzzling machines. Regrettably, the industry leaders haven’t consistently provided India with top-tier products, a void we aim to fill. We’re introducing cutting-edge global technology to India, promising reduced operational and running costs. Nonetheless, technology alone won’t resonate with customers unless it delivers tangible cost-saving advantages.

Indian companies have also realized this change and are aggressively upgrading technology, thereby shifting the market requirement. We are very confident that the entire mobile crushing and screening market will move towards Electric or Hybrid machines in the next 2 to 3 years. We definitely believe in this and therefore offer only Electric/Hybrid machines in India.

The next three years will see a significant shift towards hybrid technology

Today, Europe conducts over 70% of its business globally with hydraulic machines, and not electric. However, in India, we have embraced fully electric technology. I am certain that India will take the lead globally in the shift to electric or hybrid technology, and other countries will follow. Indian customers are adept at recognizing opportunities to save and earn money, and electric and hybrid technologies will provide the opportunities.Most of the companies in India were manufacturing hydraulic machines, so the easiest transition from hydraulic to electric is to make marginal improvements to the existing machines by adding different items to create a hybrid or dual-powered system.

What sets our machines apart is that they are entirely electric, designed from the ground up as electric machines. This isn’t a case where a hydraulic machine was converted to electric; instead, the entire design is electric-oriented. Our sizes and compactness are tailored specifically for electric machines. To put it simply, other companies have been converting machines from hydraulic to electric, but we’ve designed our machines as purely electric.

There’s a lot of confusion regarding the different types of machines-hybrid, dual power, diesel-electric, and pure electric. A ‘dual power’ machine means it operates through hydraulics, but the hydraulic operation is powered by electricity. The maintenance and OpEx costs remain largely the same as hydraulic components are retained, but the operational costs shift from diesel to electric. However, in diesel-electric or pure electric machines, there’s no hydraulic component, which means that one can eliminate maintenance hassles like hydraulic oil changes and filter replacements that occur every 2000-3000 hours of operation.

Why switch from hydraulic to electric?

Our higher capacity electric crushers produce around 100 TPH more than the competition on a like-to-like basis. For instance, when comparing a 200 TPH hydraulic machine to a 300 TPH electric machine, the electric machine saves around 7 to 8% in fuel consumption. Let’s consider for a moment that there’s no change, but we can produce an additional 100 tons per hour without consuming extra fuel. That’s an advantage for the customer.There’s a significant difference between an electric machine and a diesel-run machine in various applications. Whether it’s diesel hybrid or diesel hydraulic, the distinction is substantial. So, when electricity is available, just plug the machine in, and it’ll function directly, resulting in savings. Even in situations without access to electricity, it’s more cost-effective to operate a diesel-electric machine compared to a diesel-hydraulic one. The fuel consumption difference between diesel-hydraulic and diesel-electric machines is almost 25 to 30%. Irrespective of the manufacturer, a diesel-electric machine is far more maintenance-friendly and fuel efficient.

Electric machines: Easy Maintenance and Minimal Technical Faults

Every Keestrack machine features unique points and characteristics that no other manufacturer offers. These unique attributes are instrumental in reducing maintenance time and minimizing downtime. For instance, our jaw crusher incorporates a sliding grizzly hopper, with which one can replace the liners in half the time compared to other brands. Similarly, replacing the under-deck wire mesh takes just 30 to 45 minutes in our machine as against 3 to 4 hours in machines that do not have this feature. These attributes drastically reduce maintenance time, a critical factor for road construction and mining operations looking to maximize efficiency.One significant advantage of electric machines is that the spare part requirements are substantially reduced compared to hydraulic machines. Hydraulic machines often face hose leakage, pump, and motor issues. Electric machines, mainly motor-driven, are sturdier and experience fewer technical faults. The major difference lies in the expertise required for maintaining these machines, where the mechanic should have some electrical knowledge to handle minor issues.

Leveraging IoT and Automation to enhance productivity benefits both the customer and the manufacturer

Many OEMs are investing heavily in technology, though, in our industry, adoption is a bit slower. Information transfer, providing performance parameters of the machine to both the customer and the manufacturer is crucial, because if something goes wrong, we become aware and can alert the customer, advising them to check possible issues. However, remote functioning of a crusher although possible is not allowed due to safety concerns. Therefore, the primary purpose is preventive maintenance and monitoring the machine’s performance. Technology does come at a slightly higher cost and there may be some resistance from customers regarding the additional cost. Nonetheless, we aim to make it a standard and are actively working towards it.Indian customers, when introduced to new technologies, eventually embrace the change once they understand the benefits and are willing to pay a little extra to ensure savings. Hence, I believe that India will transition to better technologies faster than some European countries. While governments might initiate policies to lead this change, it’s the customers who are making it happen.

Investing in localization and developing own fabrication unit in India

Over-reliance on imports would jeopardize competitiveness in the market and hinder the ability to offer competitive prices. We’re investing in developing our own fabrication unit and expanding our vendor base adequately who can meet our quality requirements.When it comes to localization, there are certain constraints that we cannot ignore. Engines with the required capacity are not readily available, which presents a significant challenge. Additionally, there is an ongoing need for essential components, especially in the control and hydraulic systems. Indian hydraulic manufacturers predominantly serve the excavator and backhoe loader sectors, which align with the higher demand in our industry. However, the volumes required for these specific hydraulic components are relatively low, leading us to import them.

Recognizing the pivotal role of assembly in our operations and the availability of most OEMs in India, our primary objective is to source locally whenever feasible.

At Keestrack we’re not just selling machines; we forge enduring partnerships, offer unwavering support, and actively mould the industry’s future landscape.

Deepak Pandit, Country Manager - Sales & Marketing India

Elevating Keestrack: A Proactive Approach to Sales, Support, and Partnerships

In our relatively short journey, Keestrack has made substantial strides in expanding our reach and establishing partnerships with dealers in the Northeast, North, and West regions. While our presence in the South and neighbouring countries is a work in progress, our emphasis on sales and support for all our machines remains unwavering.

Notably, our machines’ minimal need for engine maintenance, especially when running on electricity, positions us as a frontrunner in sustainability and efficiency compared to traditional hydraulic machines.

As we pivot toward a promising future, we are committed to bolstering our brand. In the initial phase, our efforts were concentrated on meticulous data testing, ensuring that the information we convey to our customers is substantiated by concrete evidence. With over 45 machines actively contributing to various projects, we aim to solidify our position as a reliable industry player.

The current year has been instrumental in learning and comprehending the intricacies of the market’s machine landscape. Looking ahead, our focus will shift towards enhancing our visibility. Anticipate seeing us at exhibitions, passionately promoting our brand, showcasing our products, and unveiling exciting additions to our portfolio. Our collaboration with NBM&CW has been pivotal, underlining our commitment to building a brand that resonates with excellence.

In the upcoming year, we are gearing up for broader communication initiatives. We aspire not only to be a significant player in the industry but also demonstrate our prowess through tangible results. Keestrack is poised to make waves, and we invite you to join us on this exciting journey of innovation, reliability, and unparalleled service.

NBM&CW - December 2023