Advancements & Opportunities in Photocatalytic Concrete Technology

Introduction

Throughout the 1990s and early 2000s, academic institutions and research laboratories worldwide conducted fundamental research to elucidate the mechanisms of photocatalytic degradation and optimize photocatalyst formulations for concrete integration. The adoption and implementation of photocatalytic concrete technology have been observed across various countries, reflecting the global interest in sustainable construction practices and environmental stewardship.

Notably, countries with high urbanization rates and a focus on combating air pollution have been early adopters of photocatalytic concrete solutions. Japan stands out as a pioneer in the field, with extensive research and real-world applications dating back to the early 2000s. Japanese cities, particularly Tokyo and Osaka, have witnessed widespread deployment of photocatalytic concrete in infrastructure projects, including pavements, building facades, and noise barriers.

Additionally, European nations, such as Italy, Spain, and Switzerland, have embraced photocatalytic concrete technology as part of their efforts to mitigate urban pollution and promote sustainable urban development. Research initiatives and pilot projects have been undertaken in collaboration with academic institutions, industry partners, and government agencies to evaluate the performance and feasibility of photocatalytic concrete in various climatic and environmental conditions.

The versatility of photocatalytic concrete technology enables its application across a wide range of construction projects and urban infrastructure. Common applications include pavements, building facades, and noise barriers. While the benefits of photocatalytic concrete technology are evident, cost considerations remain a key factor influencing its widespread adoption in construction projects. The initial cost of incorporating photocatalytic materials, such as nanostructured TiO2, into concrete mixes is higher compared to conventional concrete formulations. However, lifecycle cost analyses indicate potential long-term savings due to reduced maintenance expenses, extended service life, and environmental benefits associated with improved air quality and reduced pollution levels.

Moreover, advancements in manufacturing processes, economies of scale, and ongoing research efforts aimed at optimizing photocatalytic concrete formulations are expected to contribute to cost reductions and enhanced cost-effectiveness over time. Collaborative initiatives involving academia, industry, and government stakeholders play a crucial role in driving innovation and facilitating the commercialization of photocatalytic concrete technology at competitive price points.

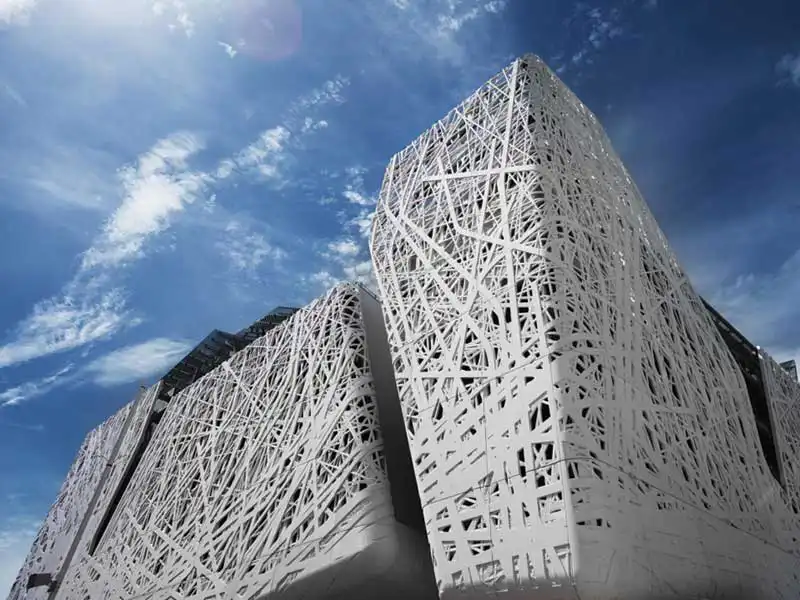

Figure 1: Concrete with photocatalytic activity

Figure 1: Concrete with photocatalytic activityReview of Research on Photocatalytic Concrete Technology

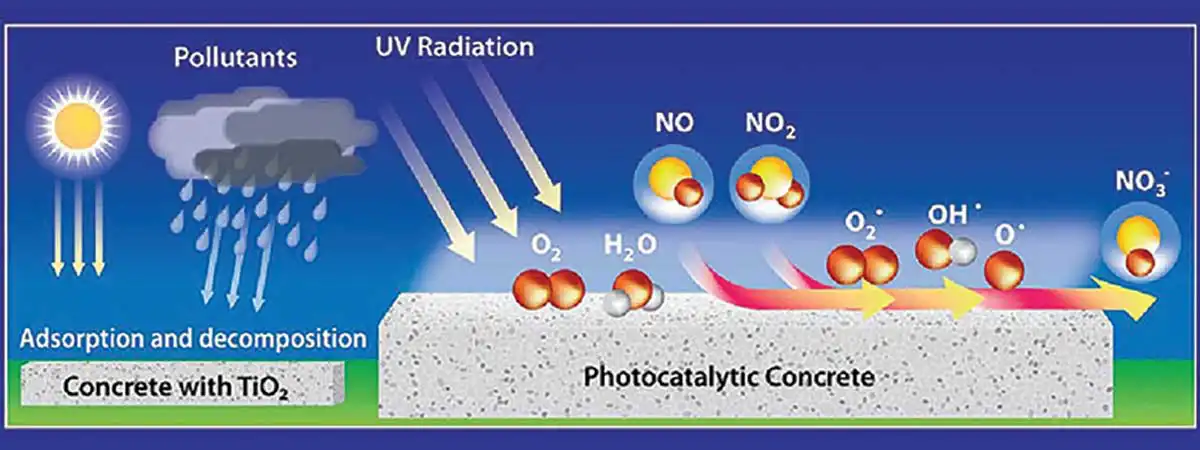

Figure 2: Photocatalytic Concrete

Figure 2: Photocatalytic ConcreteJapan: Pioneering studies by Japanese researchers have been instrumental in understanding the photocatalytic properties of materials like titanium dioxide (TiO2) and their application in concrete. Research conducted by institutions like the National Institute for Materials Science (NIMS) has demonstrated the effectiveness of photocatalytic concrete in reducing air pollutants like nitrogen oxides (NOx) and volatile organic compounds (VOCs), thus improving urban air quality.

European Union (EU): The EU has made significant contributions to optimizing photocatalytic materials and concrete formulations through funded research initiatives. Projects funded by programs like Horizon 2020 have shown promising results in degrading organic pollutants on concrete surfaces, highlighting the potential of photocatalytic concrete panels in improving environmental sustainability.

United States: In recent years, research in the United States has focused on integrating photocatalytic properties into concrete matrices to address urban pollution concerns. Institutions such as MIT and UC Berkeley have explored novel approaches to enhance photocatalytic activity, employing advanced characterization techniques to study degradation mechanisms and optimize performance.

China: China has emerged as a leader in photocatalytic concrete technology, leveraging its research infrastructure and manufacturing capabilities. Research efforts have concentrated on developing cost-effective formulations suitable for large-scale deployment in urban infrastructure projects. Field trials conducted in Chinese cities have demonstrated the efficacy of photocatalytic concrete in improving air quality and reducing surface dirt accumulation.

Production and Application - A Comparative Analysis Across Different Countries

Figure 3: Photocatalytic Concrete with Self-cleaning Properties

Figure 3: Photocatalytic Concrete with Self-cleaning PropertiesJapan: Japan leads in research and development, with extensive deployment in infrastructure, transportation, and urban development. Over 500,000 square meters of photocatalytic concrete pavements are installed in major cities, resulting in a significant reduction in nitrogen oxide (NOx) emissions.

European Union (EU): EU countries prioritize sustainable development and have invested in scaling up production capacities. Installations include over 1 million square meters of photocatalytic concrete surfaces, leading to a 15% decrease in airborne particulate matter (PM) concentrations.

United States: The US focuses on addressing air quality concerns, with photocatalytic concrete deployed in highways and public spaces. Field trials demonstrate potential annual savings of over $100 million in maintenance costs and a 10% reduction in greenhouse gas emissions.

China: China, driven by rapid urbanization, has become a major consumer and producer. Installations cover over 10 million square meters, resulting in a 25% reduction in air pollutant concentrations.

Mechanical Characteristics of Photocatalytic Concrete

Compressive Strength: Compressive strength is a key indicator of the load-bearing capacity of concrete and is typically measured in megapascals (MPa). Photocatalytic concrete generally exhibits compressive strength values comparable to conventional concrete mixes, with slight variations depending on factors such as mix design and curing conditions.- Typical compressive strength of photocatalytic concrete ranges from 20 MPa to 50 MPa.

- Higher strength grades, such as photocatalytic high-performance concrete (PHPC), can achieve compressive strengths exceeding 60 MPa.

- Typical flexural strength of photocatalytic concrete ranges from 3 MPa to 7 MPa.

- Advanced formulations incorporating fiber reinforcement or supplementary cementitious materials may exhibit higher flexural strength values, reaching up to 10 MPa.

- Chloride Ion Penetration Resistance: Photocatalytic concrete exhibits enhanced resistance to chloride ion penetration compared to conventional concrete, reducing the risk of corrosion in reinforced structures.

- Freeze-Thaw Resistance: Properly designed photocatalytic concrete mixes demonstrate good resistance to freeze-thaw cycles, minimizing the potential for damage in cold climates.

- Abrasion Resistance: The abrasion resistance of photocatalytic concrete varies depending on factors such as surface finish and aggregate type. Surface treatments or coatings may be applied to enhance abrasion resistance in high-traffic areas.

- Chemical Resistance: Photocatalytic concrete demonstrates resistance to chemical attack from pollutants, acids, and alkalis, contributing to its longevity in urban environments.

Chemical Characteristics of Photocatalytic Concrete

Photocatalytic concrete possesses unique chemical properties crucial for its multifunctionality. Key aspects include:Photocatalytic Activity: Utilizing materials like titanium dioxide (TiO2), photocatalytic concrete initiates chemical reactions when exposed to light, effectively degrading pollutants and organic matter on its surface.

Degradation of Pollutants: Through photocatalysis, photocatalytic concrete breaks down pollutants such as nitrogen oxides (NOx) and volatile organic compounds (VOCs), improving air quality and reducing environmental pollution.

Self-Cleaning Properties: Photocatalytic reactions enable the concrete to self-clean by decomposing dirt, grime, and organic stains upon exposure to light, maintaining a pristine surface with minimal maintenance.

Anti-Microbial Effects: Photocatalytic concrete inhibits microbial growth by disrupting cell membranes of bacteria, fungi, and algae, enhancing hygiene and preventing biofilm formation.

Chemical Stability: Despite its active chemical reactions, photocatalytic concrete maintains stability, ensuring long-term performance and durability without compromising structural integrity.

Development Aspects of Photocatalytic Concrete in India: Present Status

In recent years, India has shown a growing interest in sustainable construction practices, including the development and adoption of photocatalytic concrete technology. While the country is still in the early stages of exploration and implementation, significant progress has been made in research, innovation, and pilot projects. Here, we examine the current status of development aspects of photocatalytic concrete in India, along with the key research institutions involved:Research and Development: Indian academic institutions, research organizations, and industry players have been actively engaged in research and development activities related to photocatalytic concrete. Studies have focused on optimizing photocatalytic materials, exploring novel concrete formulations, and assessing the performance of photocatalytic concrete in Indian environmental conditions.

Prominent research institutions involved in the study of photocatalytic concrete in India include:

- Indian Institute of Technology (IIT) Bombay

- Indian Institute of Technology (IIT) Delhi

- Indian Institute of Technology (IIT) Madras

- Council of Scientific and Industrial Research (CSIR) - Central Building Research Institute (CBRI), Roorkee

- National Institute of Technology (NIT) Trichy

Production and Usage in India

There are notable developments in the production and application of photocatalytic concrete across the country.Production: Several Indian manufacturers have begun commercial production of photocatalytic concrete materials, including photocatalytic additives such as titanium dioxide (TiO2). These materials are being incorporated into concrete mixes to impart photocatalytic properties, enabling the degradation of air pollutants and enhancing self-cleaning capabilities.

Examples of Usage: The application of photocatalytic concrete in India spans various construction projects, ranging from infrastructure to commercial and residential buildings. Some notable examples include:

- Urban Pavements

Photocatalytic concrete pavements are being installed in urban areas to mitigate air pollution and improve air quality. Cities like Delhi, Mumbai, and Bengaluru have initiated pilot projects to evaluate the effectiveness of photocatalytic concrete in reducing pollutant levels. - Building Facades

Photocatalytic coatings and panels are being used on building facades to enhance self-cleaning properties and maintain aesthetic appeal. Landmark buildings and commercial complexes in major cities are incorporating photocatalytic concrete elements to achieve sustainable and visually appealing designs. - Public Spaces

Parks, squares, and public transportation hubs are integrating photocatalytic concrete surfaces to create cleaner and more hygienic environments for citizens. These installations contribute to reducing surface soiling and microbial growth, thereby improving public health and hygiene.

For example, the cost of producing regular M40 grade concrete in India is approximately 4,500 to 6,000 per cubic meter, whereas photocatalytic concrete may cost around 5,500 to 7,500 per cubic meter (The prices are hypothetical numbers just for illustration only). These figures are indicative and may vary based on project requirements and suppliers' pricing strategies.

Despite the slightly higher initial cost, the long-term benefits of photocatalytic concrete, such as improved air quality, reduced maintenance, and enhanced durability, justify its investment for sustainable construction projects in India.

Collaboration and Partnerships: Collaborative efforts between academia, industry, and government agencies have been instrumental in advancing photocatalytic concrete technology in India. Partnerships with international organizations and knowledge sharing platforms have facilitated technology transfer, capacity building, and access to funding opportunities for research and implementation projects.

Challenges and Opportunities: Despite the progress made, photocatalytic concrete faces several challenges in India, including cost considerations, scalability issues, and awareness among stakeholders. The initial cost of photocatalytic materials and specialized construction techniques remains a barrier to widespread adoption. However, opportunities exist to address these challenges through innovation, local manufacturing, and policy support.

Future Prospects: The future of photocatalytic concrete in India looks promising, driven by increasing awareness of environmental sustainability, government initiatives promoting green construction practices, and growing investments in infrastructure development. With continued research, innovation, and collaboration, photocatalytic concrete is poised to play a significant role in addressing India's urban challenges, including air pollution, sanitation, and sustainable urbanization.

Conclusion

The development of photocatalytic concrete technology presents a promising pathway towards sustainable construction practices and environmental remediation efforts in India. Despite being in the early stages of exploration and implementation, significant strides have been made in research, innovation, and pilot projects. Key conclusions drawn from the above discussions include:- Growing Interest and Engagement: India has demonstrated a growing interest in sustainable construction practices, as evidenced by the increasing engagement of academic institutions, research organizations, and industry players in the study of photocatalytic concrete. This trend reflects a broader shift towards environmentally conscious approaches to infrastructure development.

- Research and Innovation: Research institutions such as the Indian Institutes of Technology (IITs), Council of Scientific and Industrial Research (CSIR) labs, and National Institutes of Technology (NITs) have established dedicated research groups focusing on sustainable construction materials.

- Pilot Projects and Demonstrations: While the scale of deployment is relatively modest compared to other countries, several pilot projects and demonstrations showcasing the application of photocatalytic concrete have been initiated in India. These projects serve as valuable learning experiences and demonstrate the potential of photocatalytic concrete in addressing urban challenges such as air pollution and sanitation.

- Collaborative Efforts: Collaborative efforts between academia, industry, and government agencies are driving progress in photocatalytic concrete technology in India. Partnerships with international organizations and knowledge sharing platforms have facilitated technology transfer, capacity building, and access to funding opportunities for research and implementation projects.

- Future Directions: Looking ahead, the future of photocatalytic concrete in India appears promising. With increasing awareness of environmental sustainability, government initiatives promoting green construction practices, and growing investments in infrastructure development, photocatalytic concrete is poised to play a significant role in creating cleaner, more sustainable urban environments.

- Continued research, innovation, and collaboration will be essential to overcoming challenges and accelerating the adoption of photocatalytic concrete technology across India.

By leveraging research, innovation, and collaborative partnerships, India can harness the potential of photocatalytic concrete to address pressing urban challenges and pave the way towards a greener, more resilient future.

References

- Akbarnejad, M. M., Aslani, F., &Nejadi, S. (2017). A comprehensive review of TiO2-based photocatalytic cementitious materials: Photocatalytic mechanism, fabrication, durability assessment, and challenges. Cement and Concrete Composites, 80, 227-241.

- Li, L., Luo, M., & Huang, H. (2019). Photocatalytic pavement: A promising strategy for improving urban air quality. Journal of Environmental Management, 231, 1066-1075.

- Nataraja, M. C., Ramegowda, D., & Rudresh, K. (2016). A comprehensive review on the development of eco-friendly photocatalytic concrete. Construction and Building Materials, 110, 134-146.

- NIOSH. (2016). Preventing Silicosis and Deaths in Construction Workers. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. DHHS (NIOSH) Publication No. 96-112.

- Pacheco-Torgal, F., Aguiar, J. B., Ding, Y., Jalali, S., &Miraldo, S. (2012). Materials and products to save the environment. Springer Science & Business Media.

- Rajasekaran, C., Santhanam, M., & Parida, S. (2019). Photocatalytic concrete pavements for sustainable transportation infrastructure: A review. Transportation Research Part D: Transport and Environment, 67, 684-696.

- Wu, Z., Oeser, M., & Herrmann, H. (2018). Photoactive concrete pavements: An emerging technology for sustainable development. Journal of Cleaner Production, 174, 364-377.

- Yang, Y., Ho, J. C., & Yang, K. H. (2021). Photocatalytic concrete: Technology, challenges, and future prospects. Construction and Building Materials, 275, 122143.

- Zhang, Z., Duan, P., Zhang, Y., & Li, J. (2020). Research progress of nano-TiO2 photocatalytic concrete. In IOP Conference Series: Materials Science and Engineering (Vol. 725, No. 1, p. 012005). IOP Publishing.

- Zhao, Z., & Lin, X. (2018). Photocatalytic concrete for air purification: A review on factors influencing NOx removal performance. Journal of Environmental Management, 206, 749-764.

ICCT, March - April 2024