Self-Compacting Concrete

Workability

The workability of self-compacting concrete is measured by the usual slump cone having a base diameter of 200mm, top dia 100mm, and height 300mm. The slump cone is to be placed as usual upon a base plate square in shape and having at least a 700m side.Concentric circles are marked around the center point where the cone is to be placed. A firm circle is drawn at 500mm diameter.

Procedure of Slump Flow Test

About 6 liters of concrete is needed for this test. Place the baseplate on the ground level and keep the slump cone centrally on the base plate. Fill the cone with scoop. Do not tap. Simply strike off the concrete level with the trowel. Remove the surplus concrete lying on the base plate. Raise the cone vertically and allow the concrete to flow freely at maximum distance. Measure the final diameter of the concrete in two perpendicular directions and calculate the average of the two diameters. This is the slump flow in mm. When the slump cone is lifted, T50 slump flow is taken for the concrete to reach a 500mm mark. Time should be measured by a stopwatch. It is suggested that the T50 time may be 2 to 5 seconds.Self Compacting Concrete Benefits

- Improves constructability

- Labour reduction

- Bond to reinforcing steel

- Improved structural integrity

- Accelerates project schedule

- Reduces skilled labour

- Flows into complex form

- Reduces equipment wear

- Minimizes void on highly reinforced areas

- Produces superior surface finish

- Superior strength and durability

- Allows for easier pumping procedure

- Fast placement without vibration or mechanical consolidation

- Lowers noise levels produced by mechanical vibrators

- Produces a uniform surface

- Produces a wider variety of placement techniques.

Disadvantages of Self Compacting Concrete

- Material selection is more strict

- Construction cost increases compared with regular concrete

- Many trial batches and laboratory tests are requested to use a designed mixture

- Higher precision is required when measuring and monitoring.

Mix Design Consideration

- The coarse aggregate may be 10, 12.5 or 20mm.

- Coarse aggregate should be 45% and fine aggregate 55%.

- Water 180 to 190 Kg/m3. Normally not to exceed 200 Kg/m3.

- For M-60 and above grade concrete 10 percent of silica fume will be required.

- No silica fume needed for M-25 to M-50 concrete but 20 to 30 percent good quality flyash will be needed.

- Superplasticizer, polycarboxylic based 0.5 – 3 percent by weight of total cementious material.

- Viscosity modifying agent, polymer based 0.1 – 0.5 percent by weight of total cementious material.

Mix Design

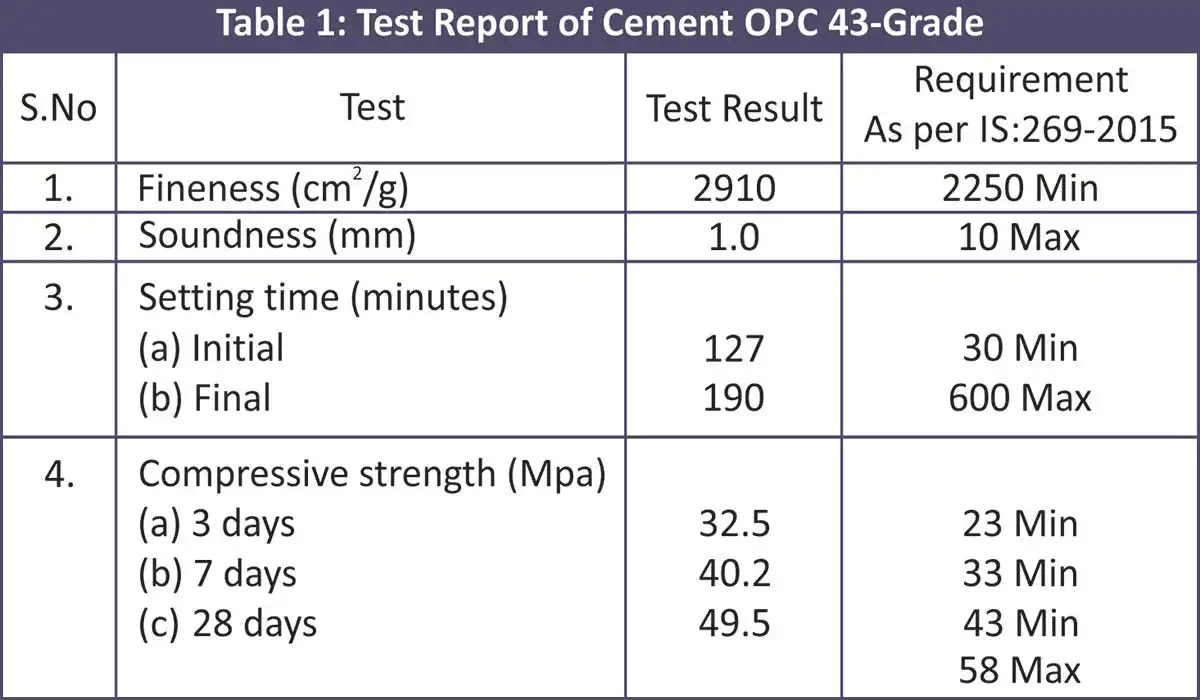

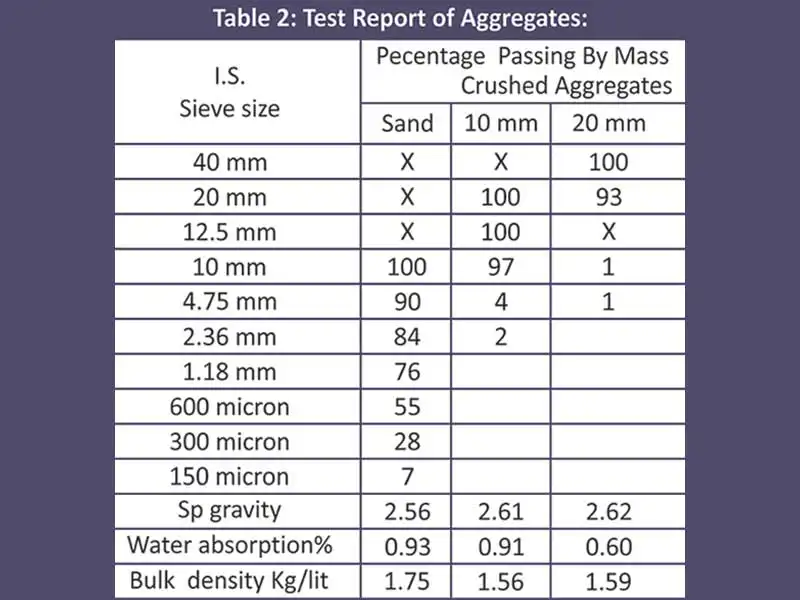

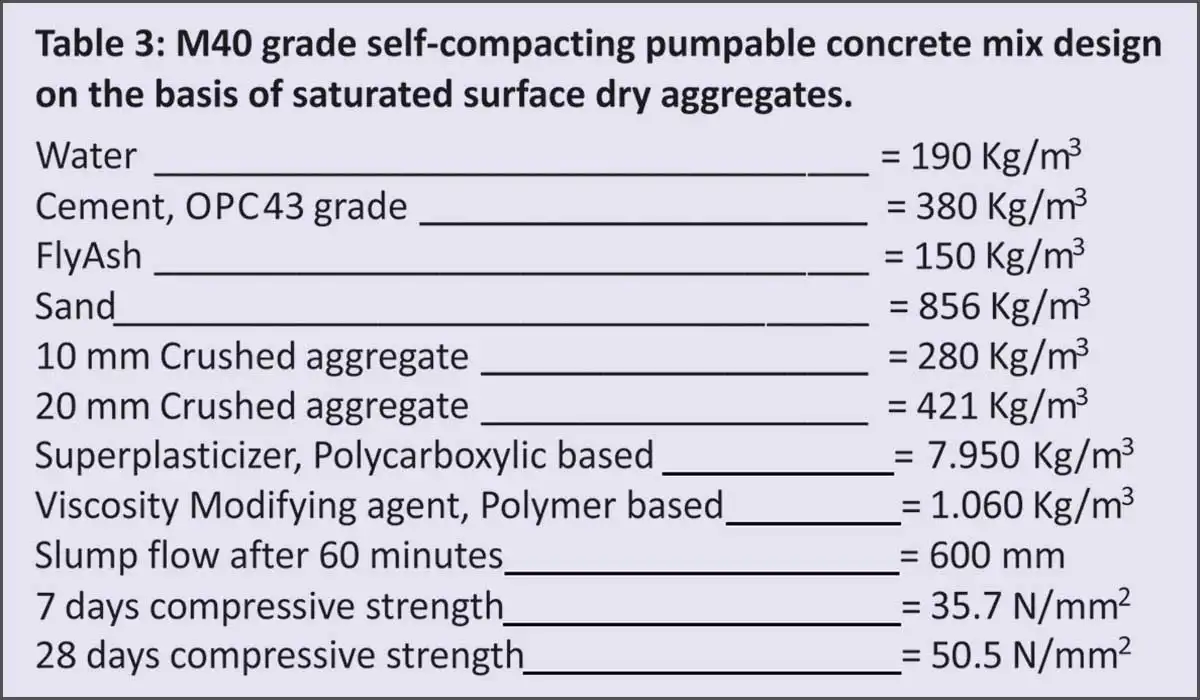

A M-40 grade self-compacting pumpable concrete is designed with cement and aggregate given in Tables 1 and 2. The mix design is given in Table 3. The mix design is carried out from reference 1.

Reference

- Concrete mix design by Er. Kaushal Kishore Civil Engineering Portal.

- Pumped concrete by Er. Kaushal Kishore google site.

ICCT, March - April 2024