Condition Monitoring Through Data Downloading

Leverage technology, educate and motivate team members, and minimise operating cost, advises Bhaskarudu Peddakotla, Consultant for Construction and Mining Equipment.

Equipment availability is critical for profitability in the construction and mining business. Delay in scheduled completion of projects - be they construction of roads, irrigation, or any other infrastructure projects, or production of coal, iron ore, limestone, or any mining activity, leads to heavy penalties to the contractors.

It is also important to get the capital cost realization at the shortest possible time (in terms of number of days) by keeping the overall lifecycle cost under control. Hence, it has become a compulsion for most of the fleet owners to run their machines to the extent of 6000 hours per year in order to meet the production targets or project completion timelines.

Such high utilization of equipment is possible only when its availability remains consistent. This is possible only by keeping a constant watch on the machine’s performance and behavior, and in case of any fault, however minor, acting immediately to rectify it.

The good news is that the new models of machines not only indicate any problem in the components, but also the operator’s behavior well in advance. This is because these new-generation machines are equipped with advanced electronics for safety and productivity and the latest technology, which is enabling easy and timely trouble-shooting of any problem. Since these machines are often deployed in tough working conditions, we need to be more alert in monitoring their health and the behaviour of people involved in their operation and maintenance.

Even though equipment manufacturers have clearly defined monitoring methods under various conditions, unfortunately, they are not being followed with the required diligence, and issues are being attended to after the machine breaks down. The modern machine communicates its problems well in advance through various means but the end-users do not pay attention, and today, we see that very few issues are being handled proactively.

Condition monitoring means keeping constant watch on the machine, and listening to it in order to take corrective action at an early stage, in case the machine indicates a problem in its proper functioning. The problem could be in a component, the operator’s behavior, or the operating condition.

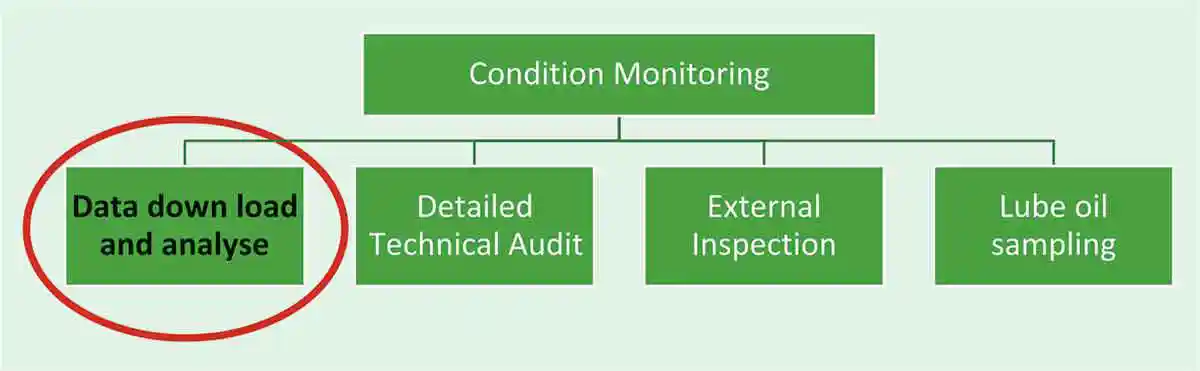

Condition Monitoring methods depend on the make and model of the machine and the operating conditions. Methods include the following:

- Data downloading from machine and analysing at regular intervals

- Machine inspection/technical audit at regular intervals

- Lubricants analysis

- Undercarriage inspections (crawler machines)

Data downloading from machine

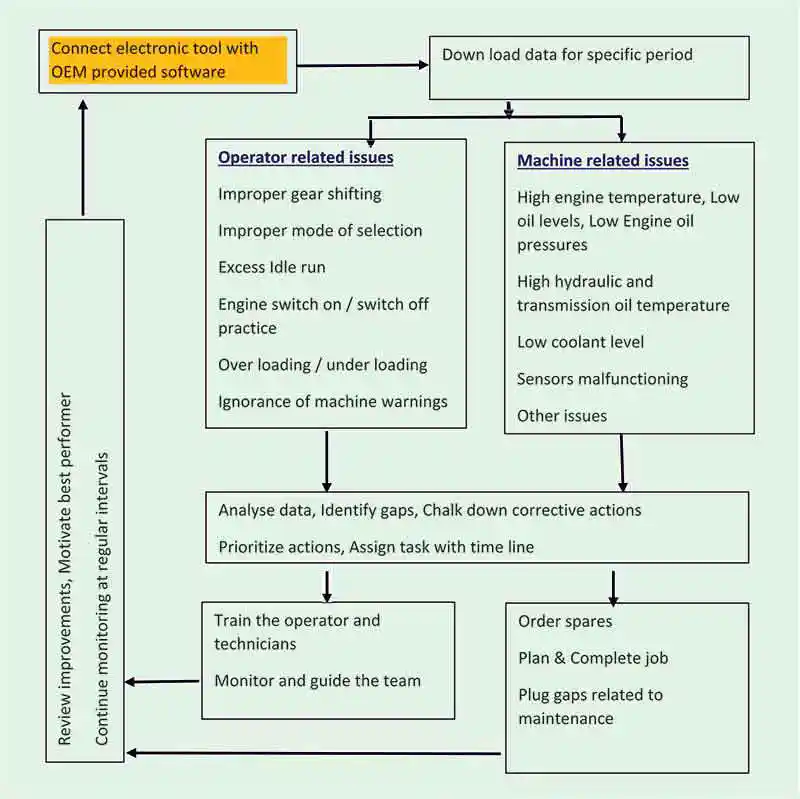

Taking data from a machine by connecting computer (which is loaded with the appropriate software) is data downloading.

Data down loading from machine and analysing: Discuss with machine manufacturer service representative and decide the frequency considering working conditions, utilization etc.,

Case study of condition monitoring through data download on a wheel loader of 500 HP deployed for loading trucks in mines

Issue: Gear shifting pattern abnormal. It is recorded that gears shifting was direct from forward to reverse and reverse to forward without allowing machine to stop a while in neutral. This happened

> 50% of total siftings for a specified time, as per the data recorded.

What happens due to such operation? Due to sudden directional changes in rotation, there is possibility of crack or even breakage of shafts and gears fitted in the drive train. Also, faster wear of clutch plates in transmission, which leads to premature failure of transmission and ultimately machine downtime and higher repair cost.

Reason for such operation: Lack of awareness or operator ignorance. Automatic transmissions are easy and smooth in changing gears as they do not require operator to press the clutch; there is no need to select gear as per load/ gradients; and gear shifting is through soft electronic buttons. Further, operators do not feel heavy jerks during gear shifting in automatic transmissions, which makes them ignore proper gear shifting during operation.

Due to such ignorance/lack of awareness, a transmission which is supposed to give life of 25,000 hrs may fail at 10,000 hrs, or even earlier. The approximate repair cost will be Rs. 40 lakh. Imagine the impact on the operating cost due to such premature failure. In addition to direct cost on repair of the affected component, there is the hidden cost in the form of machine downtime, as sometimes, the situation may demand ‘hiring’ a machine to meet the production requirement.

In the same way, many critical issues like low engine oil pressure, high engine temperature, high hydraulic oil temperature, mode of operation, air intake system, engine switch on/switch off, malfunctioning of sensors, etc., can be identified through data downloading. Hence, regular downloading and analysis of data is essential to fix the issues at an early stage with less cost incurred for maintenance of the machine, so that its availability remains consistent with minimum downtime, leading to higher production and profitability.

NBM&CW June 2020