Technological Innovation for Use of Bottom Ash by-product of Thermal Power Plants in the Production of Concrete

The day is not far for the adoption of this innovative, eco-friendly, and cost-effective bottom ash – concrete process technology by construction agencies undertaking road/infrastructure project works, real estate developers, ready mix concrete (RMC) operators, and other relevant stakeholders. This would not only turn a “waste” like bottom ash into a “value added resource material” for the construction industry, but there would be a paradigm shift from being a “cost centre” at present to a “profit centre” in the future for all thermal power stations, and which would also benefit our society at large.

Dr. Partha Ghosh, Professor of Construction Engineering Department, Jadavpur University Salt Lake Campus, Kolkata

Bottom ash as a substitute material

India depends upon coal and its products to a great extent for generating thermal power and this trend is going to continue at least for the next 20 years, despite the major focus on renewable energy generation. But the ashes generated during burning of coal, which include both fly ash and bottom ash, need some attention for their utilization. It is worth mentioning that fly ash is now considered as a “wealth” and more and more efforts are being made towards its utilization.

The use of fly ash as a raw material for producing Portland Pozzolana Cement (PPC) and manufacture of building materials from fly ash are now very common. The benefits of having turned fly ash into a “saleable commodity” are not only being enjoyed by power plants, but also by society at large, in the form of lower electricity tariff. Yet, according to the Central Electricity Authority Report for 2020-21, about 92.41% of fly ash produced was utilized. But, the large production of fly ash in India – about 214.91 million tons during the reported year, needs further application avenues to achieve the target of 100% utilization in a phased manner.

Bottom ash is another by-product generated by coal-based thermal power plants, which is yet to be gainfully utilized, as almost 85% of it is discarded in settling ponds and lagoons, or used as landfill, leading to serious environmental issues on the one hand and blocking enormous stretches of valuable land area used for constructing ash ponds by the power stations, on the other hand.

In this background, bottom ash as a substitute material for aggregate system (both fine and coarse) in concrete is attractive. Restrictions on the extraction of sand from riverbeds, pits, and other natural sources make sand a scarce material. This has spurred the opportunity of using pulverized fuel ash as a sand substitute in concrete, which in the long run would enable its large-scale application. A team of innovators from Kolkata has successfully developed a systematic approach for modifying the basic cement concrete mix by using 15 - 50% coal bottom ash as partial replacement of sand, without adversely affecting the concrete properties in fresh and hardened stages.

Innovation and Advancement

The novel process technology developed by the innovators and patented by CESC LIMITED and SDG CONSULTANTS uses bottom ash “as available” from thermal power plants without any pre-processing, screening, or sieving, as partial replacement of sand and/or cement in concrete for diverse applications, aided by a state-of-the-art and tailor-made admixture from MasterGlenium SKY GSC Series to catalyse the dispersion.

The “as available” bottom ash used in its entirety consists of coarse particle sizes resembling fine sand and extra fine particle sizes resembling cementitious material. Keeping in view the limit set by IS Code or IRC Code (for application in road works) on extent of fine aggregate that can be added to a concrete mix, the proposed technology aims for partial replacement of coarse/medium sand using the coarser particle sizes of bottom ash and replacement of cement (where such bottom ash is found to possess pozzolanic characteristics) as well as pore refinement of concrete using the extra fine particle sizes of said bottom ash.

Chemical Composition

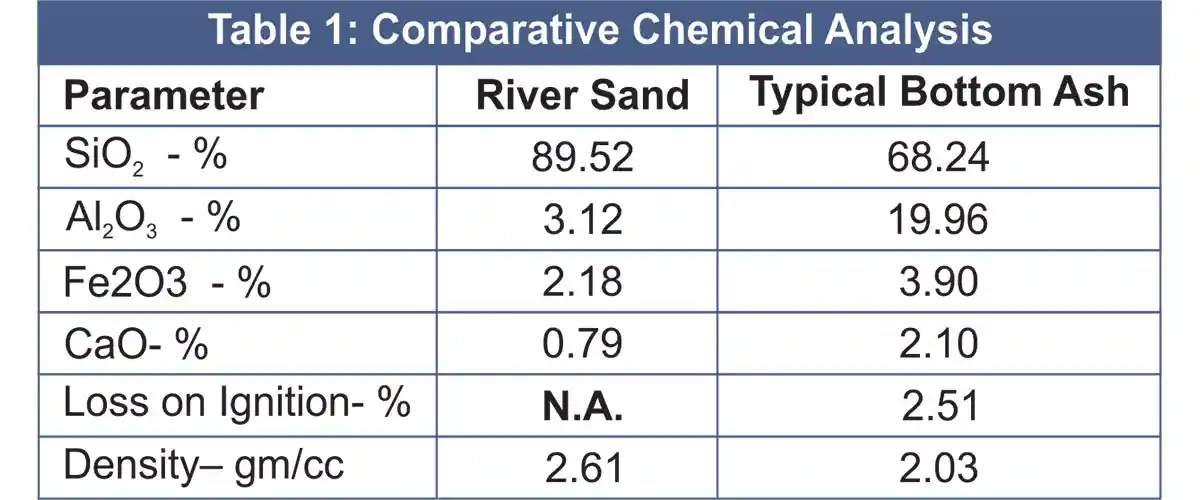

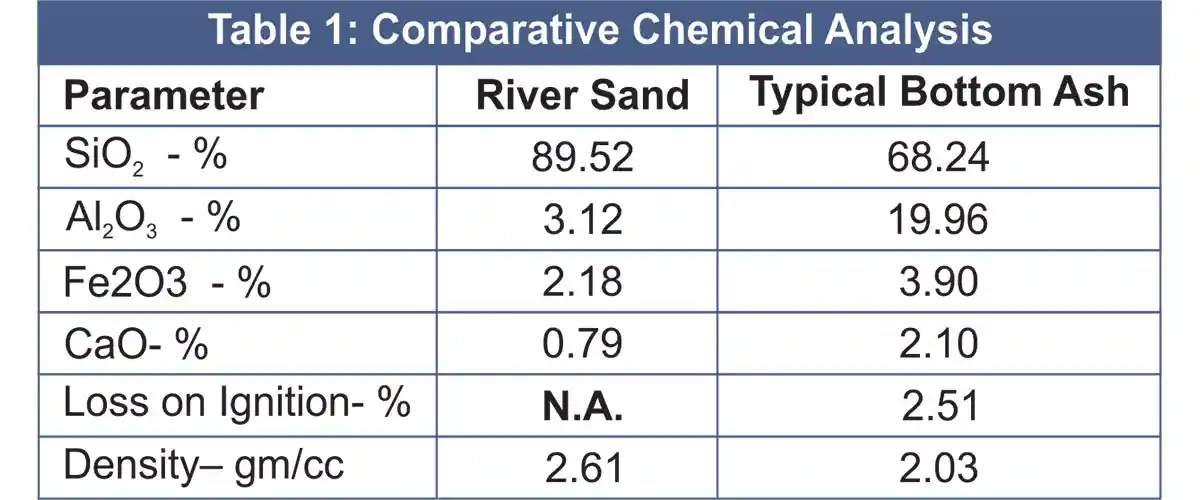

The comparative chemical composition of Coal Bottom Ash and Natural River Sand is given in table 1:

It is a well-established fact that SiO2 available in sand reacts with CaO (calcium oxide) and adds to the strength of concrete. It will be evident from the above table that coal bottom ash contains around 68.24% SiO2, which can perform the same function of sand in adding to the strength of concrete. This is known to academicians and researchers and some of them have evolved several mixes, wherein sand was suitably replaced. As sand has now become a costly as well as rare commodity and bottom ash is an unadulterated material capable of partially replacing sand in concrete, these findings remain relevant to the field.

Particle Size Distribution

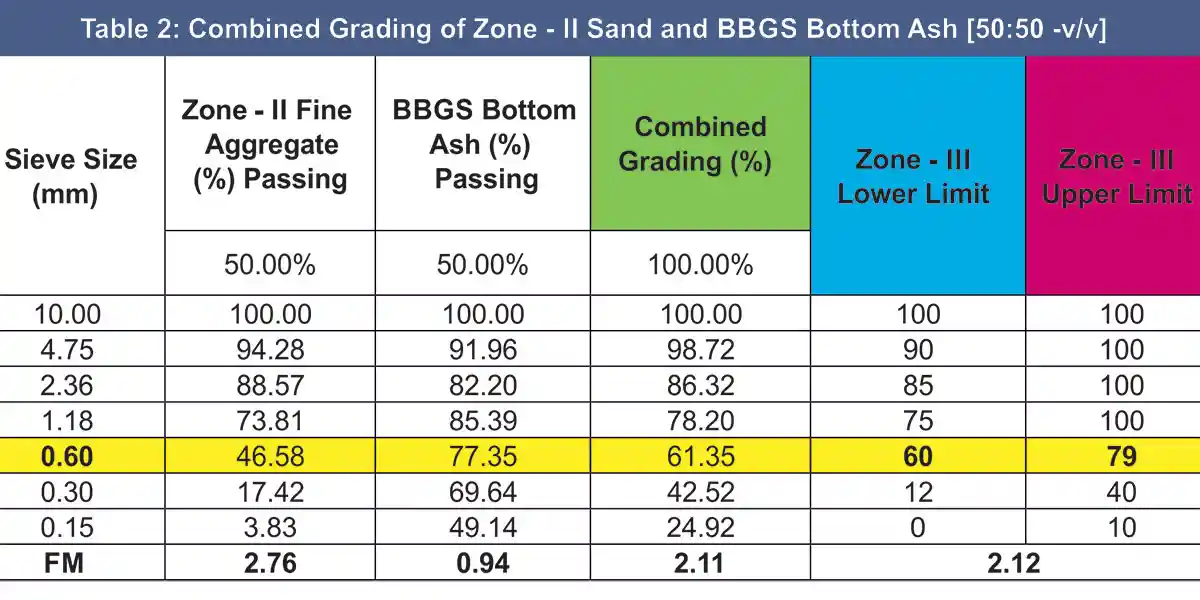

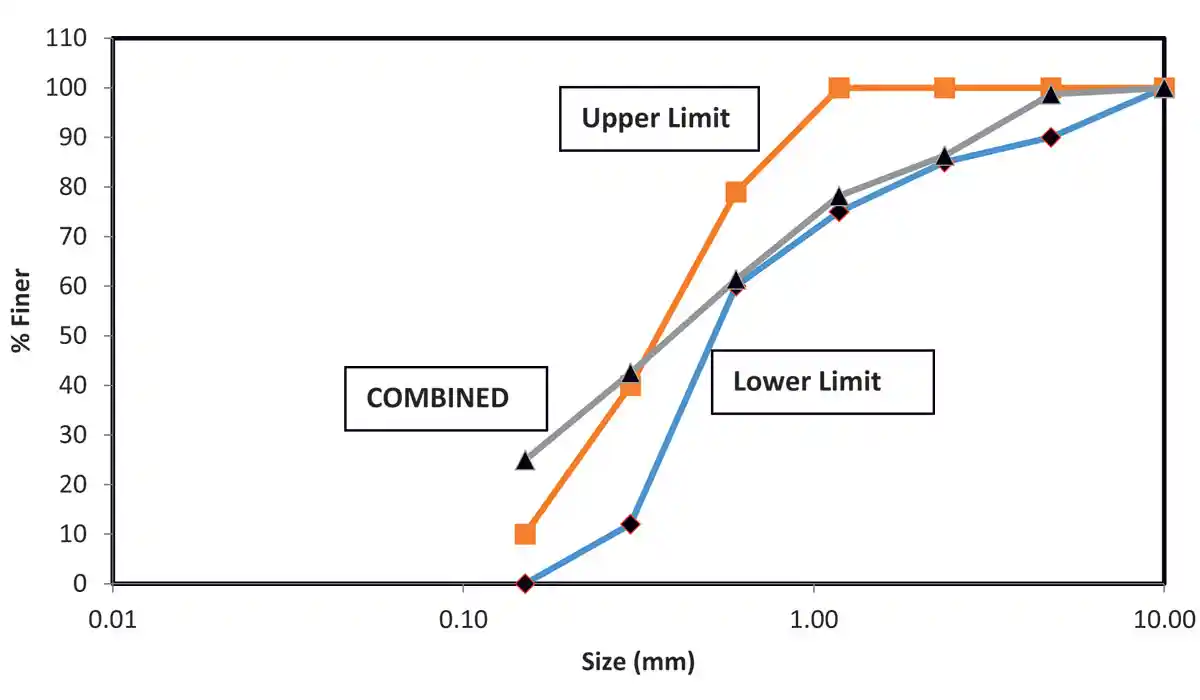

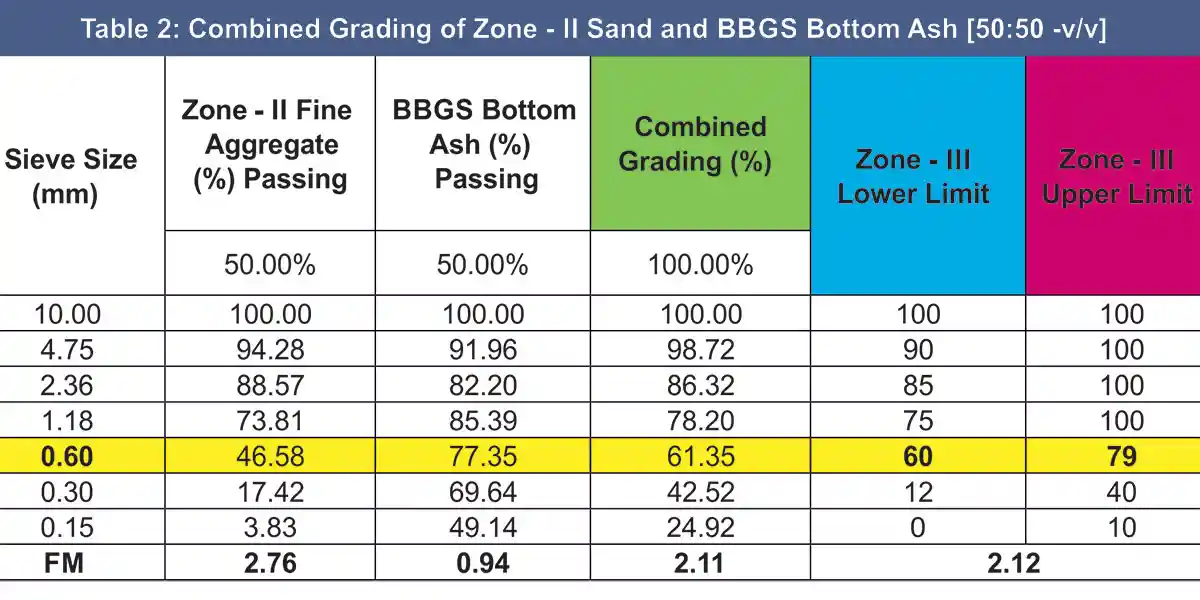

It may be observed from a sample combined zonation table and graph provided below that the “as available” bottom ash, when partially mixed with Zone-2 sand, yields a blended fine aggregate of Zone – 3. The presence of excess fine particles (combined grading % passing) as identified from data of 300 micron and 150 micron sieves have to be considered in terms of foot note no. 1 of Table – 9 (Clause 6.3) of IS : 383 – 2016.

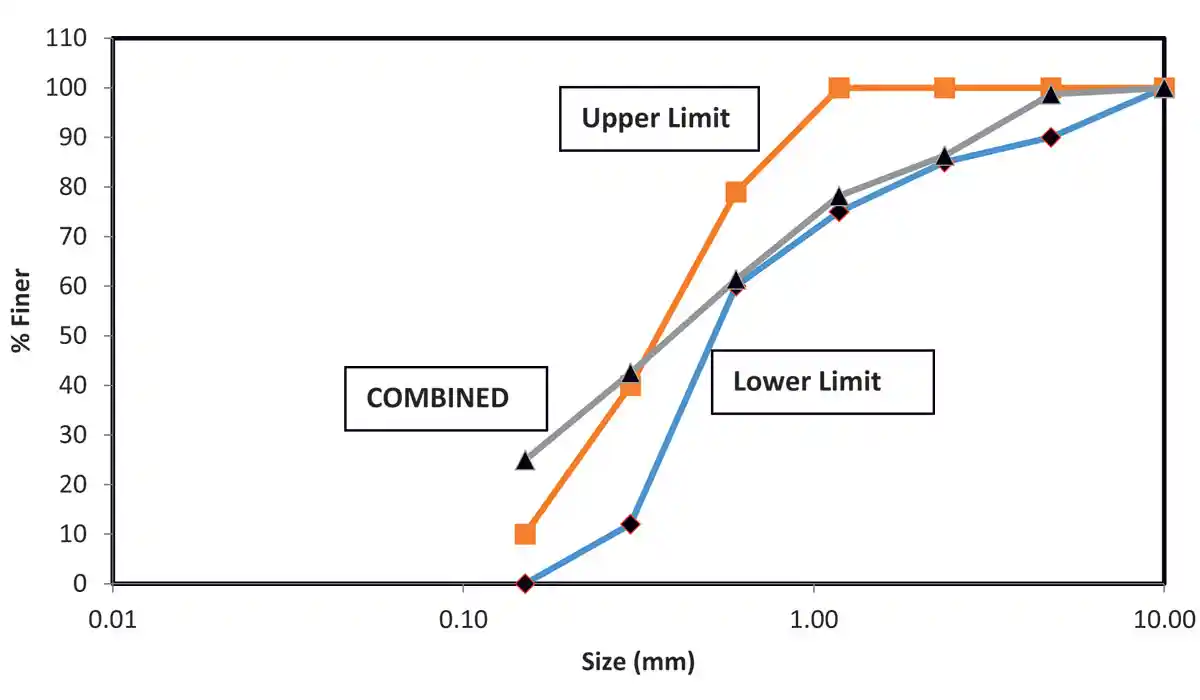

Further, it may be observed from graph-1 that the line defining particle size of blended material (i.e. sand + bottom ash marked as combined) traversing between the band of Upper and Lower limits of sand zonation is the fine aggregate that goes into the bottom ash - concrete. The lower portion of the combined line, which transgresses the band, indicates the extremely fine particles of bottom ash acting as supplementary cementitious material (SCM) and contributing to reduction in cement content as well as pore refinement of bottom ash - concrete. It will thus be clear that there will be no difficulty in evolving ideal, cost effective concrete mix.

Important Properties of Bottom Ash

While conducting durability studies on bottom ash – concrete prepared using our novel process technology, the following technical advancements of said bottom ash – concrete over conventional concrete were observed:

Trial Stretch

In the power plant premises of CESC LIMITED [Budge Budge Generating Station, Pujali, 24-Parganas (South), West Bengal] and DHARIWAL INFRASTRUCTURE LIMITED – 100% subsidiary of CESC Limited [MIDC – Tadali, Dist : Chandrapur, Maharashtra], several trial stretches of bottom ash – concrete roads have been completed, monitored by experts and found to give satisfactory service.

It is pertinent to mention here that under the stewardship of Mr. P. L. Bongirwar, Former Principal Secretary, Public Works Department, Government of Maharashtra, presentations were made before the high powered committees of Public Works Department, Government of Maharashtra, who being attracted by the techno-commercial virtues of our novel process technology using bottom ash had allowed undertaking trial stretches in the districts of Chandrapur, Nagpur, and Nashik.

The upcoming trial stretches at Chandrapur (Maharashtra) are to be monitored by VNIT, Nagpur and data collected therefrom would be shared with PWD, Government of Maharashtra, and learned members of the Codal Committee for incorporating it in the Schedule of Rates (SOR) and/or Code, as the case may be. Alternatively, it has also been a practice for the learned Codal Committee Members to consider any novel application already being adopted by industry for inclusion in the Code.

Typical Mix Design of Upcoming Trial Stretch - PWD, Chandrapur

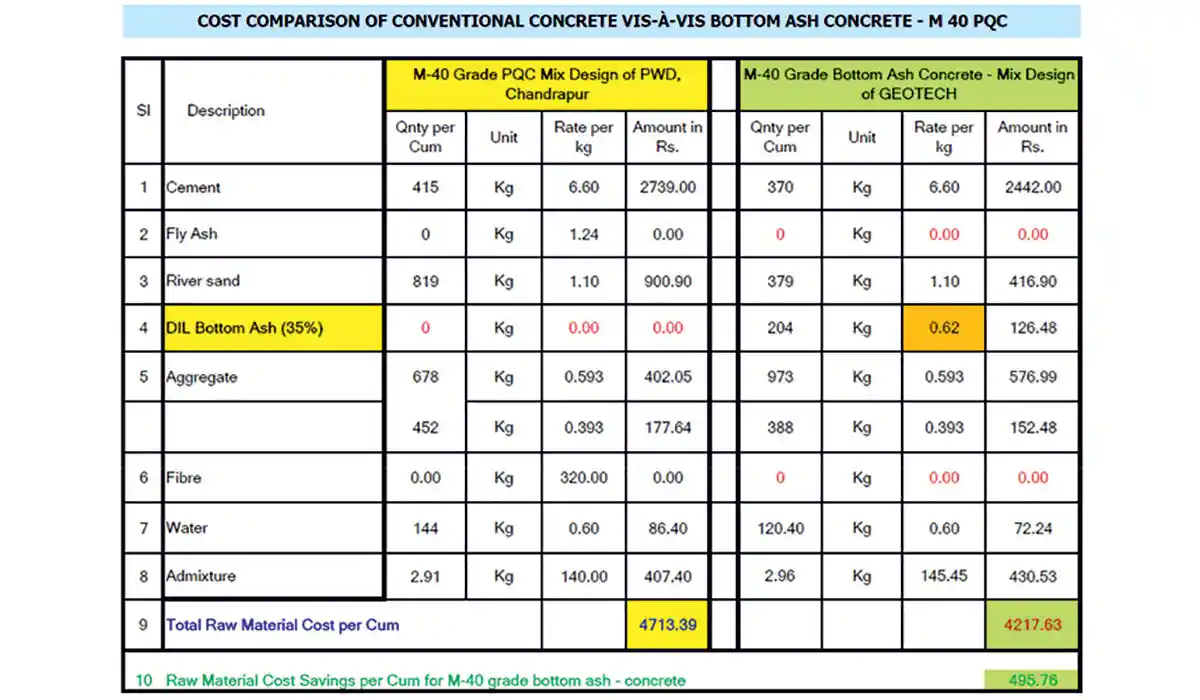

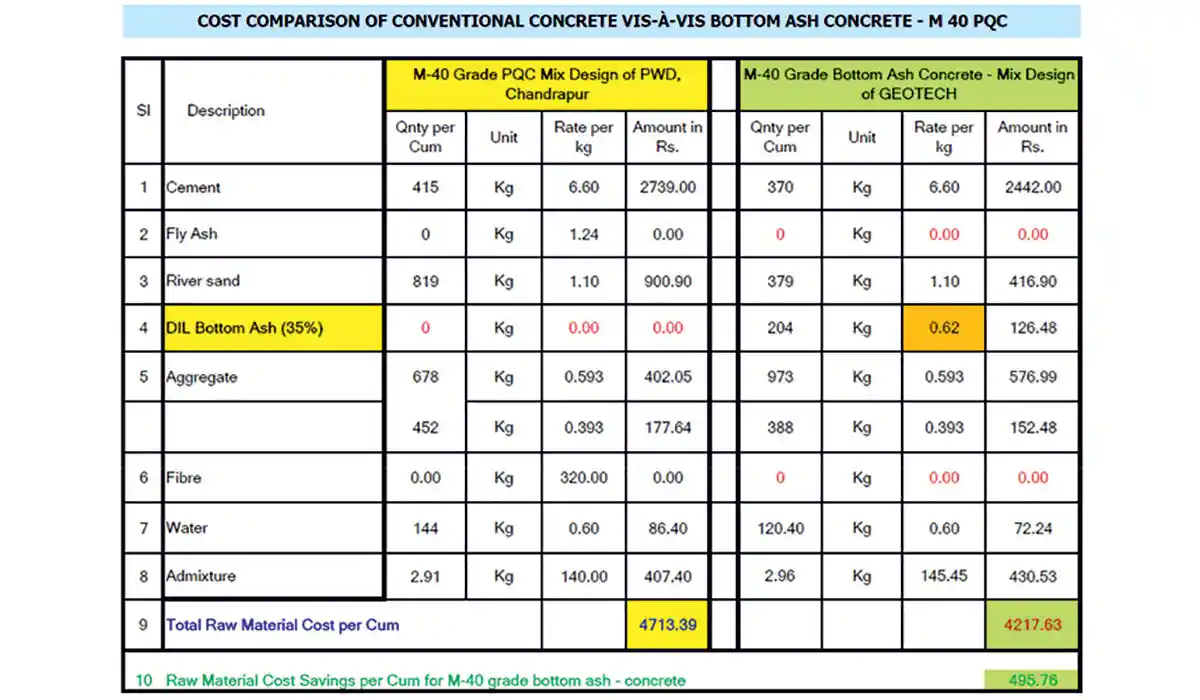

Table 3 shows the typical mix design evolved and proposed for adoption in the upcoming trial stretches of Public Works Department (PWD), Chandrapur District, Maharashtra, using bottom ash of DIL (Dhariwal Infrastructure Limited). The material and cost savings using bottom ash are obvious.

Way Forward

To validate the attributes of this novel process technology using coal bottom ash and build confidence amongst engineers and planners alike, more and more field trials need to be taken by the construction industry across India in different terrains, weather conditions, and environmental situations, under the consultancy and supervision of the patentees. This would not only facilitate collation of further data and information on the techno-commercial virtues of the patented technology for all stakeholders, but also pave the way for taking the application into the Code.

Note: The information and data provided in this article have been derived from the novel process technology jointly patented in India by CESC Limited (an RPSG Group Company) and SDG Consultants, Kolkata.

Disclaimer: The technical data, graphs and photographs provided in this article have been obtained during course of the proprietary research and remain the intellectual property of the joint patentees CESC Limited and SDG Consultants. It is not to be copied, circulated, referred to or quoted in correspondence, in whole or in part, without prior written consent of the patentees herein. By reading this article, the reader shall be deemed to have accepted the terms mentioned herein.

Dr. Partha Ghosh, Professor of Construction Engineering Department, Jadavpur University Salt Lake Campus, Kolkata

Bottom ash as a substitute material

India depends upon coal and its products to a great extent for generating thermal power and this trend is going to continue at least for the next 20 years, despite the major focus on renewable energy generation. But the ashes generated during burning of coal, which include both fly ash and bottom ash, need some attention for their utilization. It is worth mentioning that fly ash is now considered as a “wealth” and more and more efforts are being made towards its utilization.

The use of fly ash as a raw material for producing Portland Pozzolana Cement (PPC) and manufacture of building materials from fly ash are now very common. The benefits of having turned fly ash into a “saleable commodity” are not only being enjoyed by power plants, but also by society at large, in the form of lower electricity tariff. Yet, according to the Central Electricity Authority Report for 2020-21, about 92.41% of fly ash produced was utilized. But, the large production of fly ash in India – about 214.91 million tons during the reported year, needs further application avenues to achieve the target of 100% utilization in a phased manner.

Bottom ash is another by-product generated by coal-based thermal power plants, which is yet to be gainfully utilized, as almost 85% of it is discarded in settling ponds and lagoons, or used as landfill, leading to serious environmental issues on the one hand and blocking enormous stretches of valuable land area used for constructing ash ponds by the power stations, on the other hand.

In this background, bottom ash as a substitute material for aggregate system (both fine and coarse) in concrete is attractive. Restrictions on the extraction of sand from riverbeds, pits, and other natural sources make sand a scarce material. This has spurred the opportunity of using pulverized fuel ash as a sand substitute in concrete, which in the long run would enable its large-scale application. A team of innovators from Kolkata has successfully developed a systematic approach for modifying the basic cement concrete mix by using 15 - 50% coal bottom ash as partial replacement of sand, without adversely affecting the concrete properties in fresh and hardened stages.

Innovation and Advancement

The novel process technology developed by the innovators and patented by CESC LIMITED and SDG CONSULTANTS uses bottom ash “as available” from thermal power plants without any pre-processing, screening, or sieving, as partial replacement of sand and/or cement in concrete for diverse applications, aided by a state-of-the-art and tailor-made admixture from MasterGlenium SKY GSC Series to catalyse the dispersion.

The “as available” bottom ash used in its entirety consists of coarse particle sizes resembling fine sand and extra fine particle sizes resembling cementitious material. Keeping in view the limit set by IS Code or IRC Code (for application in road works) on extent of fine aggregate that can be added to a concrete mix, the proposed technology aims for partial replacement of coarse/medium sand using the coarser particle sizes of bottom ash and replacement of cement (where such bottom ash is found to possess pozzolanic characteristics) as well as pore refinement of concrete using the extra fine particle sizes of said bottom ash.

Chemical Composition

The comparative chemical composition of Coal Bottom Ash and Natural River Sand is given in table 1:

It is a well-established fact that SiO2 available in sand reacts with CaO (calcium oxide) and adds to the strength of concrete. It will be evident from the above table that coal bottom ash contains around 68.24% SiO2, which can perform the same function of sand in adding to the strength of concrete. This is known to academicians and researchers and some of them have evolved several mixes, wherein sand was suitably replaced. As sand has now become a costly as well as rare commodity and bottom ash is an unadulterated material capable of partially replacing sand in concrete, these findings remain relevant to the field.

Particle Size Distribution

It may be observed from a sample combined zonation table and graph provided below that the “as available” bottom ash, when partially mixed with Zone-2 sand, yields a blended fine aggregate of Zone – 3. The presence of excess fine particles (combined grading % passing) as identified from data of 300 micron and 150 micron sieves have to be considered in terms of foot note no. 1 of Table – 9 (Clause 6.3) of IS : 383 – 2016.

Further, it may be observed from graph-1 that the line defining particle size of blended material (i.e. sand + bottom ash marked as combined) traversing between the band of Upper and Lower limits of sand zonation is the fine aggregate that goes into the bottom ash - concrete. The lower portion of the combined line, which transgresses the band, indicates the extremely fine particles of bottom ash acting as supplementary cementitious material (SCM) and contributing to reduction in cement content as well as pore refinement of bottom ash - concrete. It will thus be clear that there will be no difficulty in evolving ideal, cost effective concrete mix.

Important Properties of Bottom Ash

While conducting durability studies on bottom ash – concrete prepared using our novel process technology, the following technical advancements of said bottom ash – concrete over conventional concrete were observed:

- Secondary reaction takes place in bottom ash – concrete due to presence of “reactive silica” in bottom ash, which consumes the unstable calcium hydroxide and converts it into strong and stable calcium silicate hydrate (C-S-H) gel. This is demonstrated through Differential Thermal Analysis (DTA) and Thermo Gravimetric Analysis (TGA), where the absence of Portlandite phase leads to lower mass loss in bottom ash – concrete in comparison to conventional concrete at elevated temperatures.

- The extremely fine particles of bottom ash contribute to pore refinement making bottom ash - concrete less permeable and more resistant to the ingress of moisture or soluble salts, which acts as an unique safeguarding feature for the steel reinforcement within the bottom ash - concrete and prolongs service life of both the steel and concrete. This is well demonstrated by the Sorptivity, Water Absorption, Chloride Migration, Rapid Chloride Penetration Test (RCPT) and Electrical Resistivity tests.

- Mercury Intrusion Porosimetry (MIP) test demonstrated the pore refinement and lower permeability of bottom ash – concrete in comparison to conventional concrete proving it to be less permeable and hence more durable even at elevated pressure.

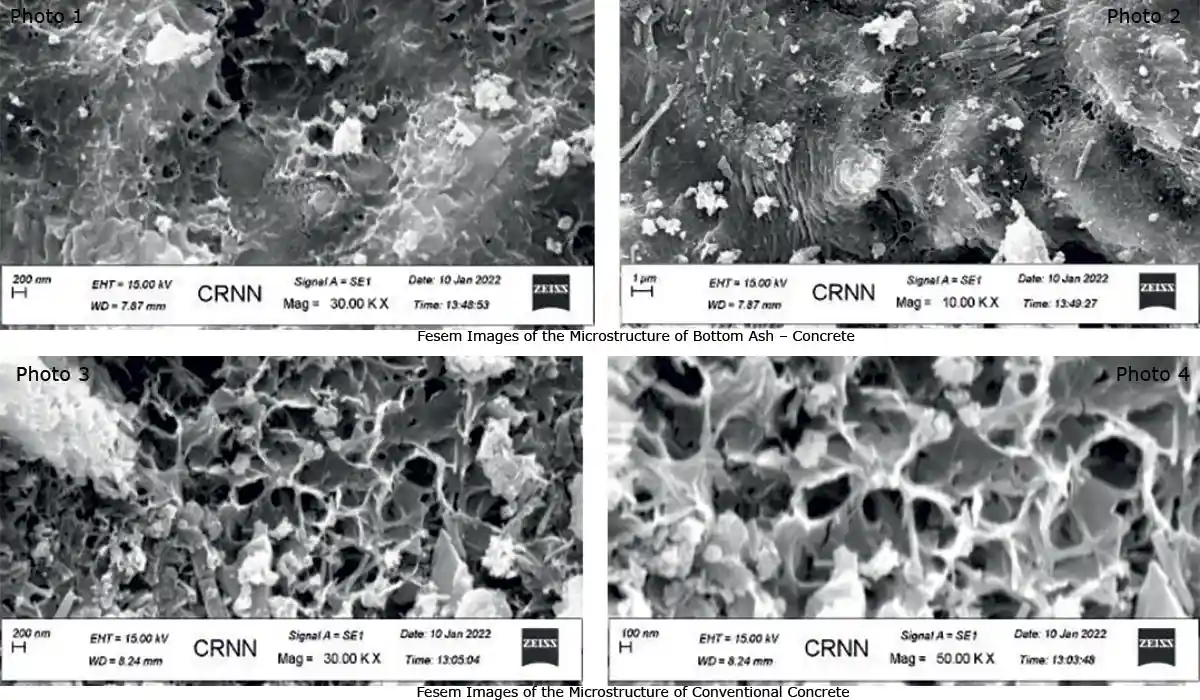

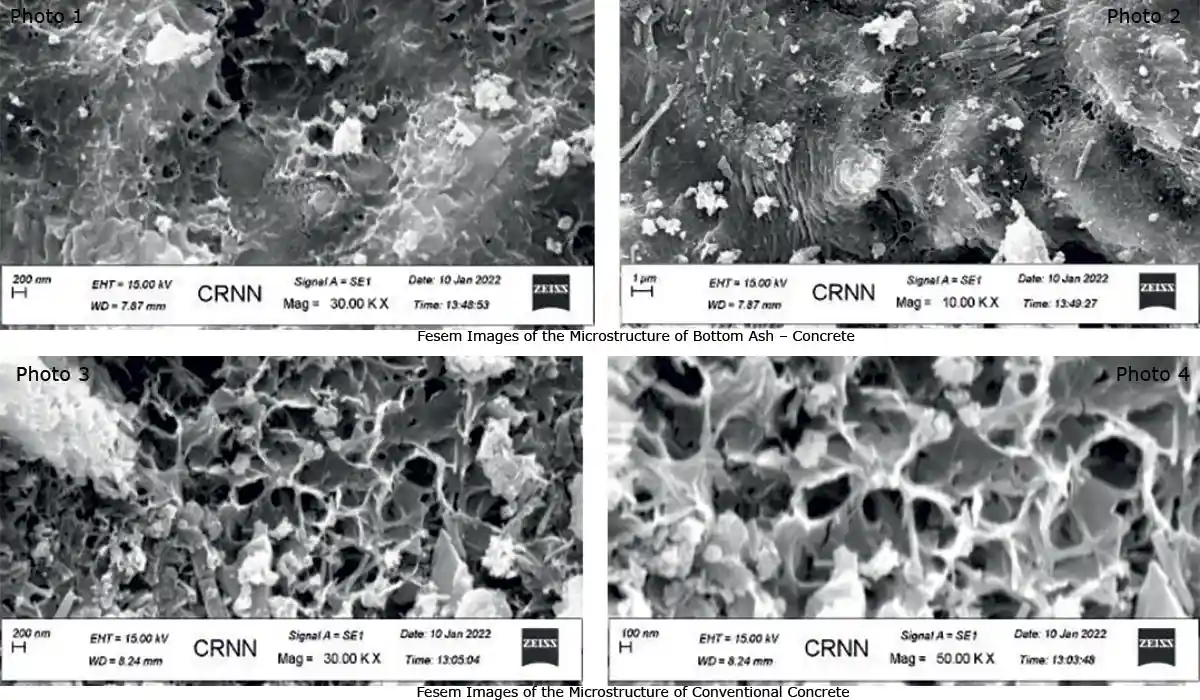

- Whereas there is no noticeable pore refinement in conventional concrete throughout the curing cycle of 28 days to 90 days and various types of pores (viz. macropores, mesopores and micropores) remain in conventional concrete making it a porous and vulnerable material, the pore sizes in bottom ash – concrete gets considerably reduced over time and at the end of 90-days’ curing cycle, the pores get confined to micropores only making bottom ash – concrete less permeable, more resistant to ingress of moisture or soluble salts, thus increasing the durability.

- FESEM images of the microstructure of bottom ash – concrete when compared with conventional concrete clearly demonstrates that bottom ash – concrete has less pores and more compact making it less permeable and more durable than conventional concrete as will appear from the photos 1,2,3, & 4.

- That bottom ash – concrete is highly resistant to adverse environment than conventional concrete has been duly demonstrated by subjecting the bottom ash concrete and control specimens to different molar solutions of sulphuric acid, magnesium sulphate and sodium sulphate in terms of tests conforming to ASTM – C 1898 - 20.

- The specific gravity of bottom ash being lower than sand makes the bottom ash – concrete lighter and lower in density than conventional concrete.

- Drying shrinkage of bottom ash – concrete is lower than conventional concrete, which will substantially contribute in controlling shrinkage cracks in concrete.

- XRD Analysis identified the presence of Albite in bottom ash – concrete, which is not present in conventional concrete. The source of this mineral is the bottom ash, which being a very hard material having 6 – 6.5 Mohs scale hardness (harder than basalt and slightly less hard than granite) lends higher strength and durability to bottom ash – concrete than conventional concrete.

- The compressive strength of bottom ash – concrete exceeds that of conventional concrete with time.

Trial Stretch

In the power plant premises of CESC LIMITED [Budge Budge Generating Station, Pujali, 24-Parganas (South), West Bengal] and DHARIWAL INFRASTRUCTURE LIMITED – 100% subsidiary of CESC Limited [MIDC – Tadali, Dist : Chandrapur, Maharashtra], several trial stretches of bottom ash – concrete roads have been completed, monitored by experts and found to give satisfactory service.

It is pertinent to mention here that under the stewardship of Mr. P. L. Bongirwar, Former Principal Secretary, Public Works Department, Government of Maharashtra, presentations were made before the high powered committees of Public Works Department, Government of Maharashtra, who being attracted by the techno-commercial virtues of our novel process technology using bottom ash had allowed undertaking trial stretches in the districts of Chandrapur, Nagpur, and Nashik.

The upcoming trial stretches at Chandrapur (Maharashtra) are to be monitored by VNIT, Nagpur and data collected therefrom would be shared with PWD, Government of Maharashtra, and learned members of the Codal Committee for incorporating it in the Schedule of Rates (SOR) and/or Code, as the case may be. Alternatively, it has also been a practice for the learned Codal Committee Members to consider any novel application already being adopted by industry for inclusion in the Code.

Typical Mix Design of Upcoming Trial Stretch - PWD, Chandrapur

Table 3 shows the typical mix design evolved and proposed for adoption in the upcoming trial stretches of Public Works Department (PWD), Chandrapur District, Maharashtra, using bottom ash of DIL (Dhariwal Infrastructure Limited). The material and cost savings using bottom ash are obvious.

Way Forward

To validate the attributes of this novel process technology using coal bottom ash and build confidence amongst engineers and planners alike, more and more field trials need to be taken by the construction industry across India in different terrains, weather conditions, and environmental situations, under the consultancy and supervision of the patentees. This would not only facilitate collation of further data and information on the techno-commercial virtues of the patented technology for all stakeholders, but also pave the way for taking the application into the Code.

Note: The information and data provided in this article have been derived from the novel process technology jointly patented in India by CESC Limited (an RPSG Group Company) and SDG Consultants, Kolkata.

Disclaimer: The technical data, graphs and photographs provided in this article have been obtained during course of the proprietary research and remain the intellectual property of the joint patentees CESC Limited and SDG Consultants. It is not to be copied, circulated, referred to or quoted in correspondence, in whole or in part, without prior written consent of the patentees herein. By reading this article, the reader shall be deemed to have accepted the terms mentioned herein.

International Concrete Construction Technology, Jan - Feb 2023