Re-Use of Old Pile Foundations in Amsterdam

Evaluating existing foundations is a common and necessary practice, not only for buildings, but also for structures like bridges that bear increasing traffic of cars and trucks, resulting in a tremendous increase in the foundation loads. Inspections to assess the adequacy of existing foundations are taken to meet the current functional requirements.

Marcel Bielefeld, Allnamics Geotechnical & Pile Testing Experts, The Netherlands

The question of the continued suitability of existing foundations arises when the function of the superstructure changes. This can occur when the superstructure is replaced or when the existing structure is expanded, leading to higher loads on the existing foundation. Obviously, the re-use of existing foundations can contribute to a more sustainable society. But this may not be the only reason why an existing foundation is to be re-used: new foundation works could cause nuisance for neighbors or even damage to the adjacent buildings, the construction lots could be too small for modern foundation equipment, or the mobilization of piles or concrete mix could be challenging.

Finally, the driver to re-use an existing and proven foundation may be simply economical, as it will not only reduce the construction cost, but also shorten the schedule. Whatever the reason, before the existing foundation can be re-used there has to be an investigation to determine whether:

- the existing foundation is able to resist the new loads?

- the integrity of the existing foundation is such that it can perform during the extended lifespan?

Obviously, the existing foundation was tested during its lifecycle, since after installation it was loaded and thus tested, albeit to loads that are unknown. The foundation behavior under these loading conditions can in part be assessed from the condition of the superstructure (e.g., through the presence of cracks, if any), and differential settlements in the superstructure. Especially the latter is a good indicator as the presence of differential settlements is a strong warning signal that (at least parts of) the existing foundation are no longer adequate. At the same time, it must be remembered that the absence of cracks and differential settlements are not a guarantee of a sound foundation.

To calculate the capacity of the existing foundation one can rely on the old engineering reports and drawings. However, the soil situation can have been changed (e.g., as a result of nearby foundation activities, ground water flow, dewatering, etc), in which case, the previously derived design values are no longer applicable. It seems therefore more appropriate to perform a new soil investigation in or near the existing foundation to calculate the capacity or to perform a load test. However, all the as-built parameters (such as pile length and diameter) have to be known for a reliable outcome of those calculations. And given the uncertainty regarding the accuracy of as-built drawings (if those are even available), it may be that the most appropriate approach is to perform a load test.

The result of a load test is the load settlement diagram, irrespective of foundation dimensions and other unknown or uncertain factors. With the load- settlement in hand, one can determine the settlement at the working load and even the foundation’s ultimate capacity (if tested up failure), which means that the investment in a load test eliminates the uncertainty of the foundation behavior.

The most suitable load test type for an existing foundation depends on the project.

- A Static Load Test can be done under the existing superstructure, where this superstructure is used as counterweight. The foundation is cut loose from the superstructure and a jack is positioned in between. After setting up load cells and instrumentation to register the settlement, the load test can start. Limitations here are the available counterweight and the stresses in the superstructure caused by the load test.

- A Dynamic Load Test (or a High Strain Dynamic Test as per the ASTM terminology) can only performed when the superstructure is demolished. Once the foundation is freely accessible, this type of test can be performed as usual, albeit that the impact stresses have to be controlled very carefully, especially in older existing foundations. Consequently, the resistance may not be fully mobilized with a dynamic load test. Additional limitations of this test method are that the impact may cause vibrations that could affect adjacent buildings and the fact that the analysis method of the test results does not have a unique solution. The Signal Matching process to interpretate and simulate the soil behaviour will have multiple solutions for the bearing capacity with similar signal match qualities, and the selection of the solution will be up to the analyst.

- A Rapid Load Test is a quasi-static test, so the load settlement diagram can be generated directly, based on measured forces and measured displacements. The maximum stresses during a Rapid Load Test are similar to that of a Static Load Test, thus avoiding the risk of pile damage. Most of the limitations listed for a Dynamic Load test do not apply to this test method: there are no issues with maximum stresses in the pile or vibrations in adjacent buildings, and the interpretation method is straightforward, and independent from the engineer who performs the analysis of the test results. However, a Rapid Load Test does also require that the superstructure is no longer in place.

Figure 1: One of the evaluated old bridges in Amsterdam, the Isa van Eeghenbrug

Figure 1: One of the evaluated old bridges in Amsterdam, the Isa van Eeghenbrug

An important factor in selecting the test method is the moment of testing. If the question about reuse of the existing foundation has to be made prior to demolishing the superstructure, then static load test is the only available option. If the superstructure is only partly demolished, a rapid load test can be performed.

When the load test shows that the existing foundation can be re-used, there is still an important question that remains: will the existing foundation have an adequate remaining design life? To answer that question the potential for future foundation material deterioration (as a result of corrosion in case of steel piles, alkali-silica reaction or loss of cover in case of concrete piles, and dry rot and decay for timber piles) needs to be assessed through inspection, in-situ testing (such as wall thickness measurements, Schmidt hammer and timber penetration hammer)) and laboratory testing.

In the old inner cities of The Netherlands, evaluating existing foundations is nowadays common practice, not only for buildings, but also for structures like bridges. Over time the traffic on the bridges in Amsterdam changed from light traffic of people, horse and carriages to that of cars and trucks, resulting in a tremendous increase in the foundation loads. Inspections had to assess the adequacy of these existing foundations whenever bridge decks are replaced to meet the current functional requirements.

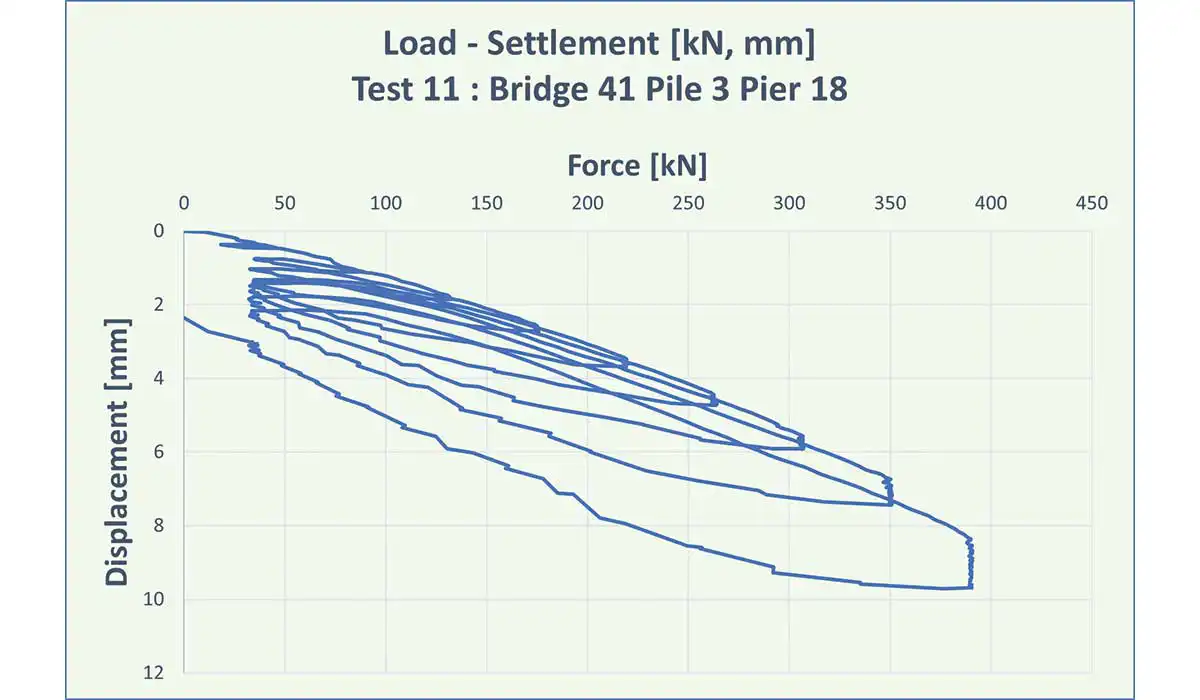

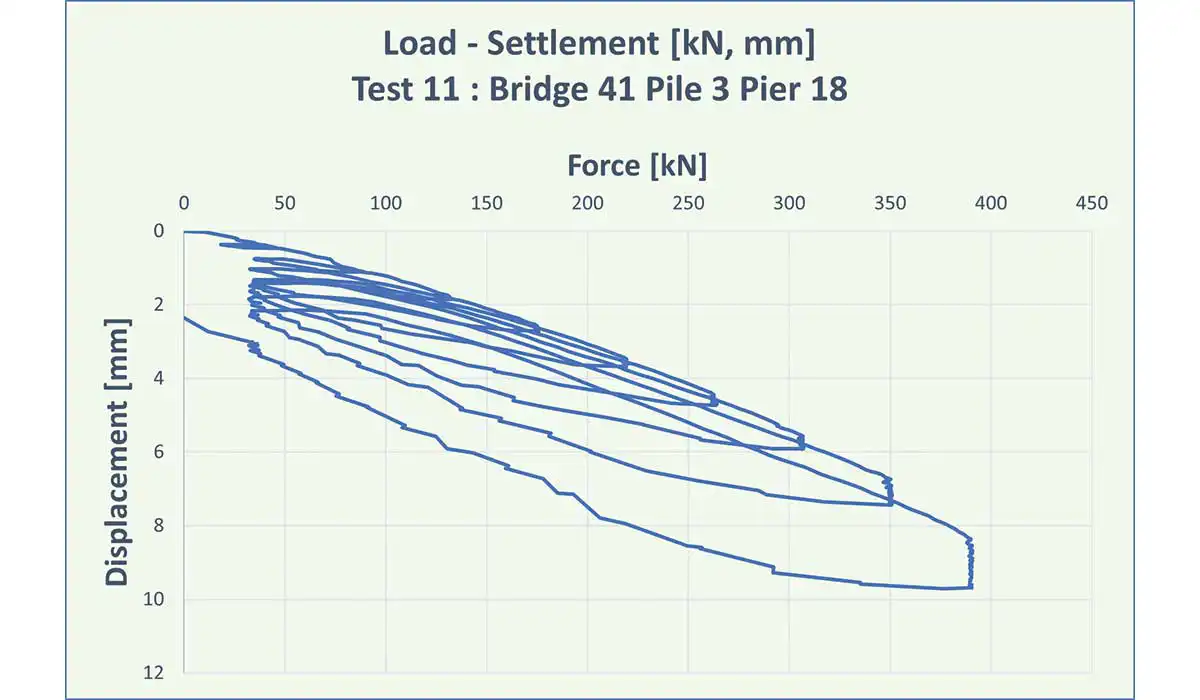

And as mentioned above, in case of a load test the test result is the load settlement diagram, such as shown in Figure 2. These results provide a very interesting insight in the behaviour of old timber piles. The assumption had been that these piles, that were installed between 1600 and 1940, had a capacity between 60 and 120 kN. However, the results indicated that the actual capacity may go as high as 420 kN, which easily explains why the existing foundations may very well be able to accommodate these tremendous increases in foundation loads.

Figure 2: Result of the static load test: the load settlement of one of the piles of bridge 41

Figure 2: Result of the static load test: the load settlement of one of the piles of bridge 41

One common misunderstanding regarding foundation re-use is that the existing foundation must be able to accommodate the entire loading from the superstructure. When the outcome of a foundation assessment is that the remaining design life is acceptable, but that the existing foundation has inadequate capacity to meet the new demands, there are still options to reuse the existing foundation. The superstructure can be designed such that loads are redistributed to an acceptable level for the existing foundation or piles can be added to supplement the existing foundation. However, such a hybrid foundation introduces a new design challenge, which is the differences in settlement between old and new foundation elements.

In any case, when the existing foundation can be re-used, it will give the owner significant advantages in costs and in construction time. And it will also contribute to a more sustainable society, where re-use, reduce and recycle is the standard.

(For the full paper see: Re-Use of Old Pile Foundations In Amsterdam Remco Offenberg, Martijn van Delft & Marcel Bielefeld, Allnamics Geotechnical & Pile Testing Experts, DFI-EFFC International Conference on Deep Foundations and Ground Improvement: Smart Construction for the Future, May 18–20, 2022 – Berlin, Germany)

Marcel Bielefeld, Allnamics Geotechnical & Pile Testing Experts, The Netherlands

The question of the continued suitability of existing foundations arises when the function of the superstructure changes. This can occur when the superstructure is replaced or when the existing structure is expanded, leading to higher loads on the existing foundation. Obviously, the re-use of existing foundations can contribute to a more sustainable society. But this may not be the only reason why an existing foundation is to be re-used: new foundation works could cause nuisance for neighbors or even damage to the adjacent buildings, the construction lots could be too small for modern foundation equipment, or the mobilization of piles or concrete mix could be challenging.

Finally, the driver to re-use an existing and proven foundation may be simply economical, as it will not only reduce the construction cost, but also shorten the schedule. Whatever the reason, before the existing foundation can be re-used there has to be an investigation to determine whether:

- the existing foundation is able to resist the new loads?

- the integrity of the existing foundation is such that it can perform during the extended lifespan?

Obviously, the existing foundation was tested during its lifecycle, since after installation it was loaded and thus tested, albeit to loads that are unknown. The foundation behavior under these loading conditions can in part be assessed from the condition of the superstructure (e.g., through the presence of cracks, if any), and differential settlements in the superstructure. Especially the latter is a good indicator as the presence of differential settlements is a strong warning signal that (at least parts of) the existing foundation are no longer adequate. At the same time, it must be remembered that the absence of cracks and differential settlements are not a guarantee of a sound foundation.

To calculate the capacity of the existing foundation one can rely on the old engineering reports and drawings. However, the soil situation can have been changed (e.g., as a result of nearby foundation activities, ground water flow, dewatering, etc), in which case, the previously derived design values are no longer applicable. It seems therefore more appropriate to perform a new soil investigation in or near the existing foundation to calculate the capacity or to perform a load test. However, all the as-built parameters (such as pile length and diameter) have to be known for a reliable outcome of those calculations. And given the uncertainty regarding the accuracy of as-built drawings (if those are even available), it may be that the most appropriate approach is to perform a load test.

The result of a load test is the load settlement diagram, irrespective of foundation dimensions and other unknown or uncertain factors. With the load- settlement in hand, one can determine the settlement at the working load and even the foundation’s ultimate capacity (if tested up failure), which means that the investment in a load test eliminates the uncertainty of the foundation behavior.

The most suitable load test type for an existing foundation depends on the project.

- A Static Load Test can be done under the existing superstructure, where this superstructure is used as counterweight. The foundation is cut loose from the superstructure and a jack is positioned in between. After setting up load cells and instrumentation to register the settlement, the load test can start. Limitations here are the available counterweight and the stresses in the superstructure caused by the load test.

- A Dynamic Load Test (or a High Strain Dynamic Test as per the ASTM terminology) can only performed when the superstructure is demolished. Once the foundation is freely accessible, this type of test can be performed as usual, albeit that the impact stresses have to be controlled very carefully, especially in older existing foundations. Consequently, the resistance may not be fully mobilized with a dynamic load test. Additional limitations of this test method are that the impact may cause vibrations that could affect adjacent buildings and the fact that the analysis method of the test results does not have a unique solution. The Signal Matching process to interpretate and simulate the soil behaviour will have multiple solutions for the bearing capacity with similar signal match qualities, and the selection of the solution will be up to the analyst.

- A Rapid Load Test is a quasi-static test, so the load settlement diagram can be generated directly, based on measured forces and measured displacements. The maximum stresses during a Rapid Load Test are similar to that of a Static Load Test, thus avoiding the risk of pile damage. Most of the limitations listed for a Dynamic Load test do not apply to this test method: there are no issues with maximum stresses in the pile or vibrations in adjacent buildings, and the interpretation method is straightforward, and independent from the engineer who performs the analysis of the test results. However, a Rapid Load Test does also require that the superstructure is no longer in place.

Figure 1: One of the evaluated old bridges in Amsterdam, the Isa van Eeghenbrug

Figure 1: One of the evaluated old bridges in Amsterdam, the Isa van EeghenbrugAn important factor in selecting the test method is the moment of testing. If the question about reuse of the existing foundation has to be made prior to demolishing the superstructure, then static load test is the only available option. If the superstructure is only partly demolished, a rapid load test can be performed.

When the load test shows that the existing foundation can be re-used, there is still an important question that remains: will the existing foundation have an adequate remaining design life? To answer that question the potential for future foundation material deterioration (as a result of corrosion in case of steel piles, alkali-silica reaction or loss of cover in case of concrete piles, and dry rot and decay for timber piles) needs to be assessed through inspection, in-situ testing (such as wall thickness measurements, Schmidt hammer and timber penetration hammer)) and laboratory testing.

In the old inner cities of The Netherlands, evaluating existing foundations is nowadays common practice, not only for buildings, but also for structures like bridges. Over time the traffic on the bridges in Amsterdam changed from light traffic of people, horse and carriages to that of cars and trucks, resulting in a tremendous increase in the foundation loads. Inspections had to assess the adequacy of these existing foundations whenever bridge decks are replaced to meet the current functional requirements.

And as mentioned above, in case of a load test the test result is the load settlement diagram, such as shown in Figure 2. These results provide a very interesting insight in the behaviour of old timber piles. The assumption had been that these piles, that were installed between 1600 and 1940, had a capacity between 60 and 120 kN. However, the results indicated that the actual capacity may go as high as 420 kN, which easily explains why the existing foundations may very well be able to accommodate these tremendous increases in foundation loads.

Figure 2: Result of the static load test: the load settlement of one of the piles of bridge 41

Figure 2: Result of the static load test: the load settlement of one of the piles of bridge 41One common misunderstanding regarding foundation re-use is that the existing foundation must be able to accommodate the entire loading from the superstructure. When the outcome of a foundation assessment is that the remaining design life is acceptable, but that the existing foundation has inadequate capacity to meet the new demands, there are still options to reuse the existing foundation. The superstructure can be designed such that loads are redistributed to an acceptable level for the existing foundation or piles can be added to supplement the existing foundation. However, such a hybrid foundation introduces a new design challenge, which is the differences in settlement between old and new foundation elements.

In any case, when the existing foundation can be re-used, it will give the owner significant advantages in costs and in construction time. And it will also contribute to a more sustainable society, where re-use, reduce and recycle is the standard.

(For the full paper see: Re-Use of Old Pile Foundations In Amsterdam Remco Offenberg, Martijn van Delft & Marcel Bielefeld, Allnamics Geotechnical & Pile Testing Experts, DFI-EFFC International Conference on Deep Foundations and Ground Improvement: Smart Construction for the Future, May 18–20, 2022 – Berlin, Germany)

NBM&CW SEPTEMBER 2023