Reverse Circulation Drills a Solution for Large Dia Marine Piles

Suretech Infrastructure is offering the very efficient, safe, and environmentally friendly BUMA Reverse Circulation drilling technique for a wide range of pile diameters, deep holes, and holes drilled into hard rock in various projects across India.

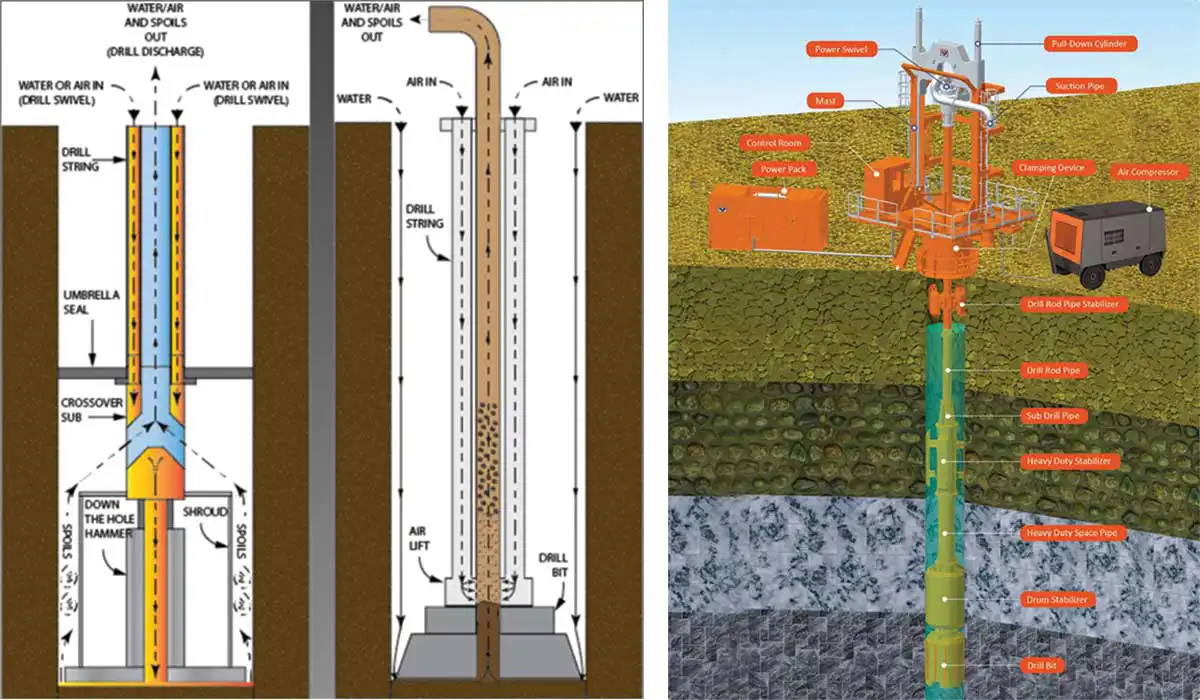

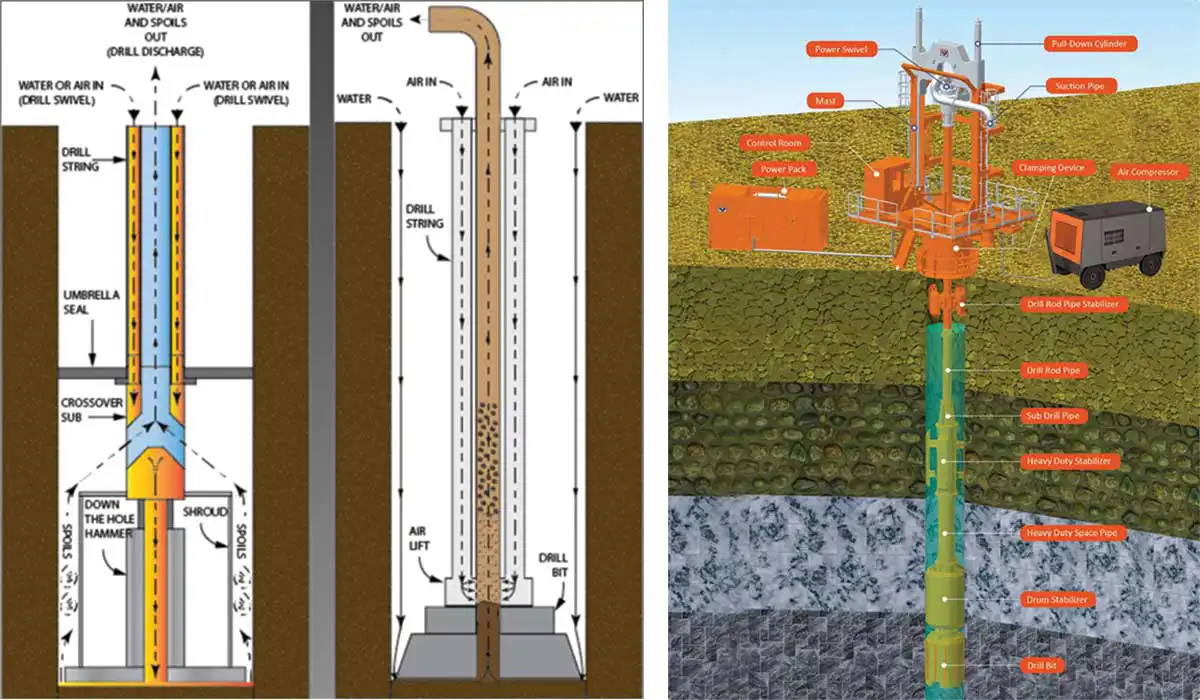

Reverse Circulation Drilling (RCD) system, also known as air-lift, works on the principle of injecting compressed air into the drill pipe below water level just above the drill bit. This reduces the density of internal water column and starts circulation. The mixture of water, air and cuttings are then flushed out through the drill pipe into the settling tanks.

BUMA drilling systems are designed to maximize production rates through hard rock. Productive drilling occurs when the majority of the time spent on-site is devoted to actually drilling and not in machine set up. BUMA RCD’s do just that.

BUMA ‘Reverse Circulation’ drilling involves the supply of air down through the drill-string to decrease the ‘effective density’ of the water in the centre of the drill-string. Operating much like an ‘air-lift’, the drilling spoils are carried out of the hole through this rising column of lower-density air/water mixture (see Figure 1). Reverse Circulation requires that the outer annular area of the casing be kept full of water in order to provide the hydraulic head required to effectively ‘push’ the central column of air/water/spoils up and out of the hole through the central pipe of the drill-string.

BUMA ‘Reverse Circulation’ drilling involves the supply of air down through the drill-string to decrease the ‘effective density’ of the water in the centre of the drill-string. Operating much like an ‘air-lift’, the drilling spoils are carried out of the hole through this rising column of lower-density air/water mixture (see Figure 1). Reverse Circulation requires that the outer annular area of the casing be kept full of water in order to provide the hydraulic head required to effectively ‘push’ the central column of air/water/spoils up and out of the hole through the central pipe of the drill-string.

Reverse Circulation is an effective drilling technique for a wide range of pile diameters including very large piles of even 3m diameter and larger. It is also effective for very deep holes, and holes drilled into hard rock. Working with RCD Rigs is a highly efficient, safe, and environmentally friendly solution for drilling large diameters and depths. If your project has one of the following requirements, RCD will provide the best solution:

BUMA RCD has been successfully used in the Bandra-Worli Sea Link, the Mumbai Trans-Harbour Link, and is currently being used in the Versova Bandra Sea Link.

Daewoo-Tata Projects used BUMA RCDs in the MTHL project. The piling job was completed in 2022 where DAEWOO –TPL undertook 840 nos. of 2m dia piles using 6 BUMA RCDs. The drilling depth was up to 35mtr at a drilling speed of 500mm per hour.

Also, for the first time in India, 3m dia piles were successfully completed using a. BUMA RCD model BM 3030. 8 piles having depth of 30m, completed successfully at a drilling rate of 400mm per hour.

In BUMA records, the deepest drilling depth recorded in South Korea was during the construction of Incheon Bridge, reaching 80 meters.

In the United States, the KYTC Kennedy Mill Bridge Replacement project achieved a drilling depth of 90 meters.

For a Hong Kong project, the excavation reached a depth of 127 meters. On the Greater Male Connectivity ‘Male to Thilafushi’ Link Project in the Maldives, contractor Afcons informed that their team successfully completed concreting of one of the deepest piles in the project which was bored using BUMA RCD. Afcons is also confident of it being the world’s deepest cast-in-situ Pile Foundation.

BUMA RCD has established itself as the world Leader in the field of Circulation Drills. Its constant endeavour to improve upon the product has resulted in the current machine, which has proven itself time and again across the globe in the most stringent of conditions. The name BUMA denotes reliability, not just in terms of the equipment, but also the after-sales service provided by the company and its representatives.

Reverse Circulation Drilling (RCD) system, also known as air-lift, works on the principle of injecting compressed air into the drill pipe below water level just above the drill bit. This reduces the density of internal water column and starts circulation. The mixture of water, air and cuttings are then flushed out through the drill pipe into the settling tanks.

BUMA drilling systems are designed to maximize production rates through hard rock. Productive drilling occurs when the majority of the time spent on-site is devoted to actually drilling and not in machine set up. BUMA RCD’s do just that.

The drilling process

Common applications of RCD

- Rock drilling

- Rock socketing

- Underreaming

- Bell-out of rock socket

- Pile cutting

- Milling of deformed casings

- Anchor drilling

- Secant wall drilling

“Suretech is proud to be associated with BUMA for the past 15 years,” informs, Sunil Newatia Chairman & MD, Suretech Infrastructure. ”Our customers are confident of the synergy we share with BUMA and we ensure customer satisfaction through innovative solutions and timely product support. We have had a 100% success rate with the deployment of BUMA RCDs in various projects. We are also proud to say that we have contributed in a positive and environmentally friendly manner to the growth and development of Infrastructure in the country.”

Reverse Circulation is an effective drilling technique for a wide range of pile diameters including very large piles of even 3m diameter and larger. It is also effective for very deep holes, and holes drilled into hard rock. Working with RCD Rigs is a highly efficient, safe, and environmentally friendly solution for drilling large diameters and depths. If your project has one of the following requirements, RCD will provide the best solution:

- Large Diameter (more than 800 mm)

- Deep Depth (more than 50 m)

- Hard Rock Drilling ( ~ 350 MPa)

- Bore Piling in Marine Condition

BUMA RCD – the best choice for Foundation Contractors

For foundation contractors, a BUMA Reverse Circulation drill is definitely the best choice. It is the most ruggedly designed and extensively field-tested all-purpose drills in the foundation industry. The reliable and powerful RCD is the most suitable for large dia rock drilling for marine structures viz jetties, berths, dry docks, bridges and piers.BUMA RCD has been successfully used in the Bandra-Worli Sea Link, the Mumbai Trans-Harbour Link, and is currently being used in the Versova Bandra Sea Link.

Daewoo-Tata Projects used BUMA RCDs in the MTHL project. The piling job was completed in 2022 where DAEWOO –TPL undertook 840 nos. of 2m dia piles using 6 BUMA RCDs. The drilling depth was up to 35mtr at a drilling speed of 500mm per hour.

Also, for the first time in India, 3m dia piles were successfully completed using a. BUMA RCD model BM 3030. 8 piles having depth of 30m, completed successfully at a drilling rate of 400mm per hour.

In BUMA records, the deepest drilling depth recorded in South Korea was during the construction of Incheon Bridge, reaching 80 meters.

In the United States, the KYTC Kennedy Mill Bridge Replacement project achieved a drilling depth of 90 meters.

For a Hong Kong project, the excavation reached a depth of 127 meters. On the Greater Male Connectivity ‘Male to Thilafushi’ Link Project in the Maldives, contractor Afcons informed that their team successfully completed concreting of one of the deepest piles in the project which was bored using BUMA RCD. Afcons is also confident of it being the world’s deepest cast-in-situ Pile Foundation.

BUMA RCD has established itself as the world Leader in the field of Circulation Drills. Its constant endeavour to improve upon the product has resulted in the current machine, which has proven itself time and again across the globe in the most stringent of conditions. The name BUMA denotes reliability, not just in terms of the equipment, but also the after-sales service provided by the company and its representatives.

NBM&CW SEPTEMBER 2023